Design Support & Material Specification

Conceptual design support

Graphics design support

Requirements specification

Exploring alternatives

Materials selection

Supplier qualification

Engineering & Manufacturing

Detailed technical specification

CAD drawings

Value engineering

Design for manufacturability

Validation samples

Prototypes

Assembly

Packaging

Turnkey outsourced manufacturing.

Supply Chain Services

Customized packaging and labeling

Order cost minimization

Private labeling

Traceability tracking

Inventory management

Drop shipment

Lot customization

Kanban & inventory management

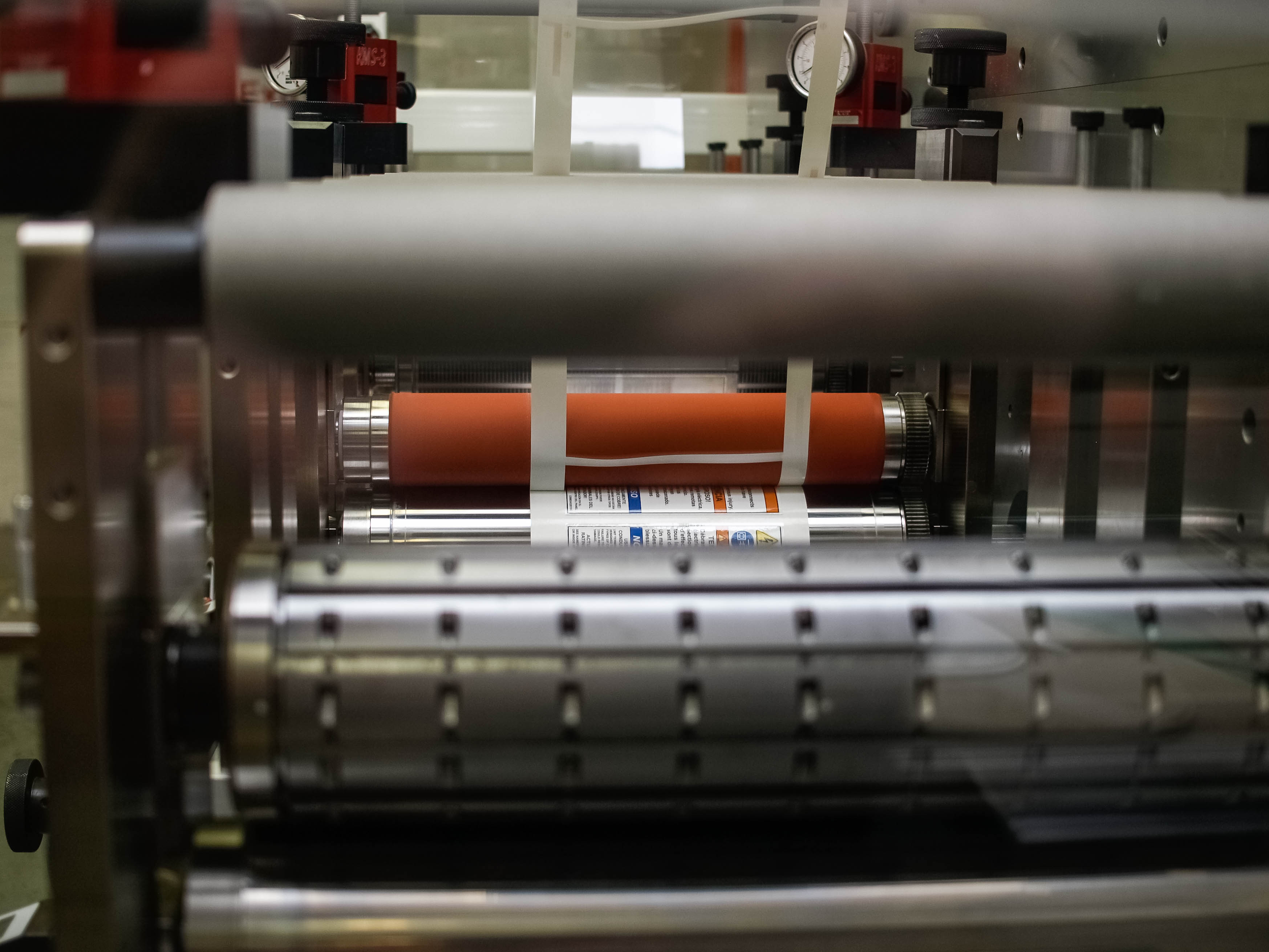

Production Capabilities

CUSTOM MATERIAL CONVERTING

Tapecon has capabilities for precision slitting, die-cutting, laminating, coating and printing for a wide variety of materials.

Material Expertise

Our experience with challenging products in many unique specialized applications means we work with a wide range of materials. We can support material selection to meet your application, performance, and cost goals.

Durable Printing

Our printing capabilities include digital printing, flexographic printing and screen printing for industrial labels, membrane switches, security printing, product packaging and more.

Outsourced Manufacturing

Tapecon can offer turnkey production of components, subassemblies or complete packaged products involving printing and converting capabilities.

Let's Get Started

To learn more about partnering with Tapecon, fill out this short form and a Tapecon representative will follow up with you as quickly as possible. As a fifth-generation family business, we pride ourselves on being trusted manufacturing partners for our clients, and we look forward to working with you.

What Our Clients Say

"Tapecon reviewed our proposed design and gave us prompt professional assistance."

Research Engineer

"Great interaction and professionalism for a start-up product component."

Supply Chain Consultant

"Good communication from customer service."

Purchasing Manager

"What my company appreciates most is their flexibility should we need an order or a partial sooner than the due date at the time of order submission. These attributes make them stand out in their industry!"

Senior Buyer

Recent Articles

We regularly publish content to serve our fellow colleagues in the advanced manufacturing industry.

.png)