Healthcare and Life Sciences Solutions

Advancing Patient Care through Specialized Medical Manufacturing

Overview

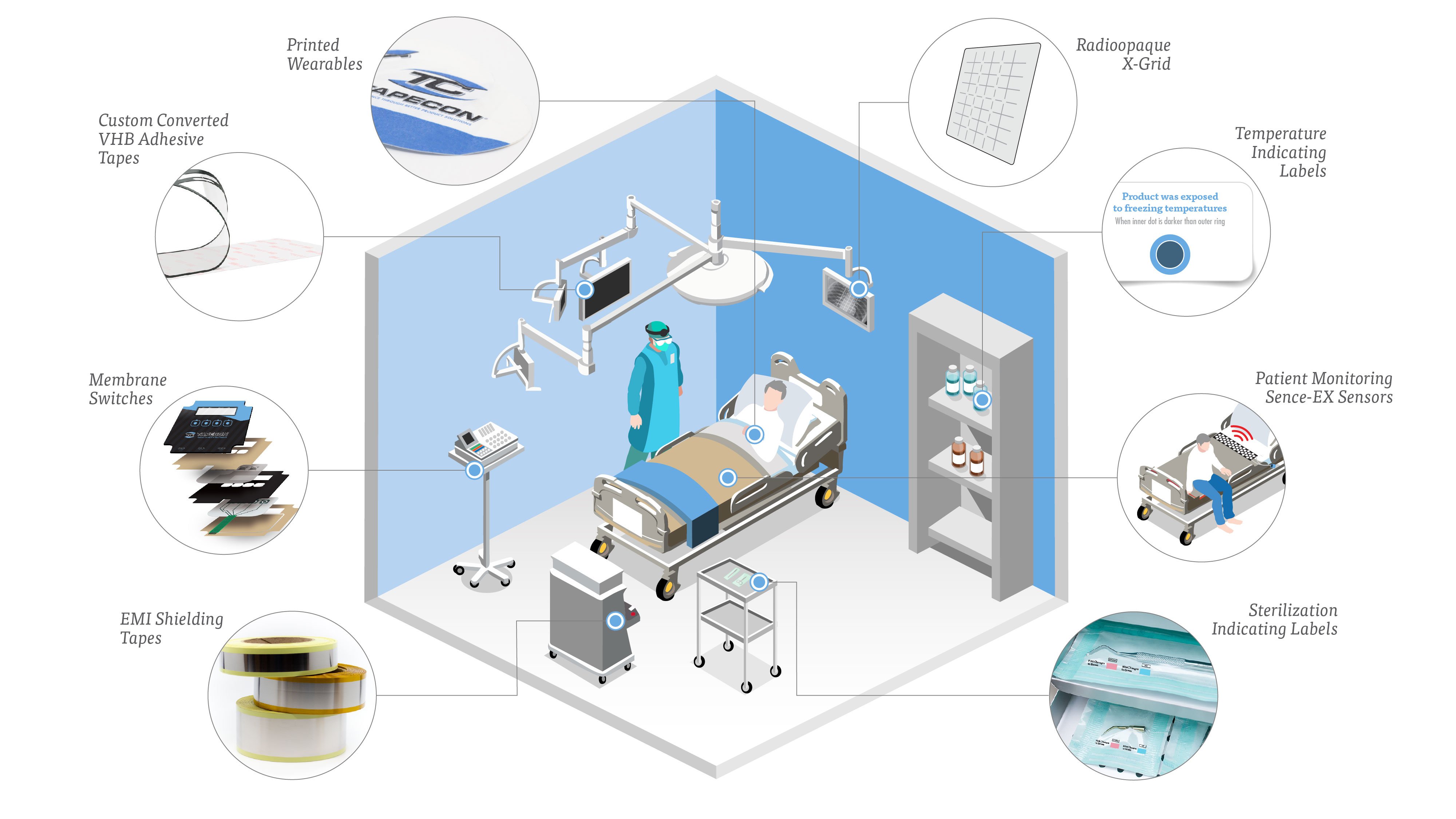

With each healthcare and life sciences product we design, assemble, or produce, we keep the final destination in mind: supporting a patient in surgery, monitoring the well-being of a newborn child, informing a consumer invested in their personal health, or empowering medical personnel and caregivers to have the data insights they need to make sound decisions for their remote patients, their loved ones, or themselves.

With this awareness of how our design and production efforts impact patients and consumers, our goal is to support our customers leading medical and life science companies in creating the best possible products for their customers. This starts in-house with quality management systems and compliance protocols that exceed governmental and industry standards. For our clients, we provide dedicated support throughout the entire design, assembly, and production process, emphasizing transparency, quality, and customization to meet the exact specifications of the product design and application.

From medical device labels to wearable patches, cohesive tape, graphic overlays, and disposable medical components, we offer a wide range of design and manufacturing services that advance the work of leading companies invested in producing reliable medical and life sciences products. In each phase of the production process, we operate as an invested partner, adapting to the vision you have for your product while offering personalized support throughout our entire collaboration.

Medical Device Labeling

Medical device label printing impacts hospitals, medical facilities, home care environments and the well-being of staff and patients alike. That’s why we apply rigorous standards to our printing, sanitization and compliance processes to meet or exceed governmental and industry standards.

When labels or graphics are properly applied to the packaging, instructions, or main components of a medical device, they ensure proper use by medical personnel, prevent allergic reactions or other physical injury, and instill confidence in the products a medical company has provided to healthcare facilities or consumers.

Adapted to Meet Your Needs

Throughout our customizable design, assembly, and manufacturing process, we ensure that each label we create aligns with your needs and specifications and is subject to stringent quality control processes and current good manufacturing practices (cGMPs).

Regardless of the complexity of the medical device you aim to produce, we work closely with you to develop an approved label design and fulfill all requests to meet regulatory, operational, and security standards as we construct and manufacture your product. Along the way, we offer comprehensive data (ERP system traceability) about the raw materials we use and specifications regarding all of the labels we create, emphasizing transparency and accessibility.

Accommodating a Range of Uses

Whether it’s a label for a wearable sensor, diagnostic device, patient monitoring equipment, or another more specialized medical devices, we offer the expertise, tools and manufacturing capacity to design and produce all of the following medical label types:

- Smart / NFC labels - equipped with sensors and a mechanism to securely communicate the data collected (passively: ie. RFID, NFC of actively: ie. BLE, WIFI, LoRa, GSM, etc)

- Stick-to-Skin Wearables – Health & Wellness, Athletic performance and Remote Patient Monitoring for everything from sleep studies to fall detection and vitals monitoring.

- RFID labels – equipped with HF/UHF technology that sends and collects information using radio waves without requiring a line of sight between scanning device and label: highly useful for inventory monitoring, product tracking, authentication, and other applications.

- Extended Content labels – EFLS are used to convey extensive information while utilizing a folding or pop-out function that compresses initial label size; this can include Information for Use (IFU) labels, as well.

- Piggyback labels – a two-layered label with one layer that can be removed from the packaging; offers double the label space to convey important regulatory or operational information. This can include (IRC’s) Instant Redeemable coupons sold at retail.

- Warning & Safety (ANSI) labels – designed to prevent operational misuse and warn users of potential dangers (ANSI – American National Standards Institute markings)

Label Features

- Condition Indicator Labels – Light-activation, temperature excursions, moisture activated or other indicators offer additional operational or safety information for a variety of products or medical devices

- Tamper-Proof Security – Tamper-evident features offer additional security and authentication layers to prevent the misuse, counterfeiting or contamination of medical devices

- Specialized text, images, and foils – Whether it’s a QR code, micro-printing, taggants, void pantographs, or other security features, can prevent counterfeiting and tampering at multiple stages of product/device rollout.

Health and Personal Care Labeling

In the vitamin and nutraceutical industries, customers closely evaluate packaging and labeling to determine a product’s alignment with their health-conscious goals. Proper labeling creates a positive first impression of the product, relays important regulatory information, and demonstrates the benefits of product use. It’s aesthetically pleasing and informative labeling that is essential for all health and personal care products.

If your product is designed for use in a life sciences, biotech, nutraceutical context, we can create informative and visually appealing labeling that promotes your product and conveys important information to consumers.

We offer all of the following health and personal care labeling services:

- Product ID labels

- Extended content and booklet labels

- Double-sided or multilayered labels

Wearable Patches

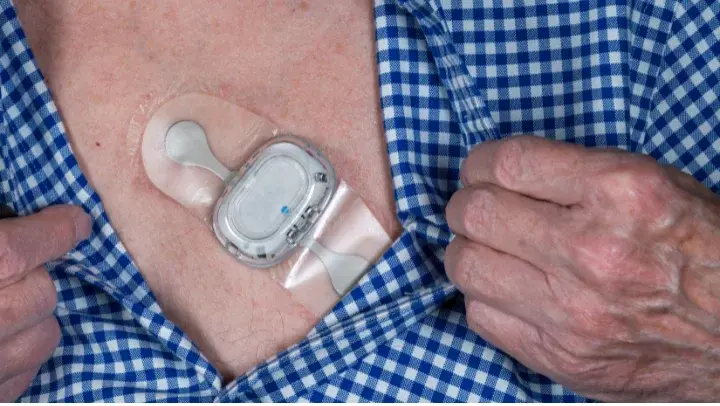

Printed wearable patches serve a range of important functions, including improving patient diagnosis, treatment, monitoring, and even facilitating drug delivery when using transdermal patches. Whether a wearable patch is disposable, durable, or transdermal, it must comfortably adhere to skin – a sensitive and complex surface – and function reliably in a range of settings.

Tapecon offers high-quality design and adhesive components to match the intended application of any wearable patch product. Emphasizing performance, safety, and consistency, we use medical-grade materials and adhesives from reputable suppliers to create customized wearable patches from scratch, meeting all of your exact specifications and ensuring the product’s applied use is successful (keeps the wearable securely attached for the wear period and then removes easily with no irritation or sticky residue left behind). As an FDA-registered manufacturer, we design and manufacture in full compliance with federal and industry standards and can work upon request with ISO 10993 biocompatible materials.

.jpg)

Design, Adhesive, and Converting Possibilities

Regardless of whether your product is in the prototyping phase, about to be commercialized, or has been in production for many years, we operate as a dedicated partner. We offer design and manufacturing support, as well as guidance on material choices, budgetary best practices, and focused work to meet all shipment timelines.

Since customized wearable patches can be used for a range of purposes, it’s important to have options when choosing adhesives that support product application. We offer access to a wide range of acrylic, rubber-based, hot melt, and silicone adhesives. To add to the customization of your product, we also provide a wide range of converting approaches to your finished patches, including the following and more:

- Graphic printing

- Precision slitting

- Die-Cutting

- Laminating

- Non-woven and foam layers

- Packaging

- Printed indicating and conductive inks

Anti-Microbial Membrane Switch, User Interface Keypads, and Graphic Overlays (Infection Control)

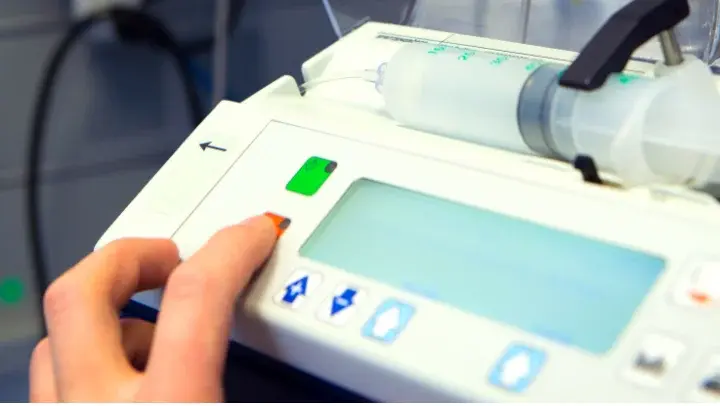

Anti-microbial membrane switches, user interface keypads, and graphic overlays all play a key role in ensuring intuitive control and operation of medical devices and products. When properly and responsibly designed, they feature hard-coated but flexible antimicrobial materials that provide infection control and ensure safety when operated in a range of settings, including home use.

Anti-Microbial Membrane Switches

An anti-microbial membrane switch is an electrical controller that turns a circuit on and off and offers multiple advantages over a traditional manual switch. Because the switch is made from a flexible substrate and combines a graphic overlay and electrical switch into one integrated unit, the operation is easier for users, the control panel/interface has a more modern appearance, and the use of antimicrobial materials offers an important layer of protection against infection.

Our designers and engineers can develop an anti-microbial membrane switch that matches your product specifications, using CAD and other advanced software to formulate an ideal solution. This could include all of the following electrical components as part of your unique product design:

- EL backlit panels

- Elastomeric keypads

- Racetrack, pillow, or custom embossing

- ESD, RFL, and EMI shielding

- Hybrid switches or PC board

- Modular, edge, or pin connectors

Once we’ve collaboratively developed an ideal design, our expert personnel and ISO-certified facility can produce a product that fulfills all operational and aesthetic expectations while meeting regulatory requirements.

User Interface Keypads and Graphic Overlays

User interface keypads and graphic overlays provide protection from environmental conditions, assure infection control, and simplify user operation of any medical device – all while adding a significant visual improvement to the most frequently used component of a product.

Tapecon uses industry-leading materials to develop customized overlays and user interface keypads with hard-coated antimicrobial materials and other material/design options to create features specific to your product. Whether it’s a unique design for display windows, backlighting, and embossing, or the use of distinct die cuts, adhesives, and textures, we can accommodate your design, printing and production needs. When you need support with more than design and production of overlays, we can even help with the assembly, testing, and delivery of machine interface units to ensure quality control through each phase of the project.

Ryandra Cohesive Tape

Ryandra cohesive tape is an industry-leading solution for coiling and taping medical tubing, electrical cabling, and other life science products. A residue-free tape option that only sticks to itself, it is available through Tapecon in 15 standard sizes, but can be customized to meet the needs of your specific product or application.

Each phase of Ryandra cohesive tape production is completed in our facilities in full alignment with ISO 9001:2015 standards to meet and exceed our customers’ quality expectations.

Disposable Medical Devices and Components

Tapecon offers extensive expertise and resources to support the design and production of disposable medical devices and components. With the awareness that these products will assist with wound care, surgical processes, ECG/EKG functionality and other high-priority applications, we emphasize high standards of design, ISO-compliant quality management, and responsible production to ensure the medical devices and components we produce fulfill all regulatory requirements.

To support customization, we offer years of experience manufacturing Class I and II disposable devices/components that can be adapted to include unique features specific to your product and its intended application(s). From precision rotary die cutting to kitting, packaging, cold seal pouching or producing multi-layered laminations, we adapt to the specific needs of your product and complete all assembly or manufacturing in our climate-controlled, FDA-registered production facility.

Blog Posts

Read our latest articles and best practices on outsourced manufacturing.

Podcasts

On Tapecon’s Better Product Solutions Podcast, we have insightful conversations with engineers, product managers, procurement managers, and a variety of professionals in the manufacturing space to explore a simple pursuit – how we can make products better.

Podcast: David Liebl of Intricon on Wearable Sensors

| April 17, 2024

In this episode, we chat with David Liebl, Chief Commercial and Technology Officer at Intricon, a contract development and manufacturing organization..

Podcast: Jon Burgoon from Mativ on Wound Therapy

| October 25, 2023

In this episode, we spoke with John Burgoon, Medical Sales Manager for Mativ. Mativ manufactures advanced medical materials, composites, and..

Podcast: Bret Ludwig from 3M on Wearable Medical Skin Tape & Adhesives

| August 6, 2020

In this episode, we talked to Bret Ludwig, Senior Product Development Engineer at 3M. We talk a wide-ranging conversation with medical skin tapes on..

Ensure High-Quality Product Design and Manufacturing with Tapecon

The reliability of healthcare and life sciences products depends on stringent quality control, full regulatory compliance, and dedication to combining high-quality source materials with expert design and production practices. At Tapecon, we offer over 100 years of experience supporting the design and production of customized medical and life sciences products.

From creating prototypes to full-scale production and printing, we adapt to meet your needs and fulfill the intended specifications of any product you design. Contact us today to discuss your project and start the process.

Let's get started. Book a Meeting with Us.

As a fifth-generation family business, we pride ourselves on being trusted manufacturing partners for our clients, and we look forward to working with you.

.jpg)