CONTACT TAPECON

Contact Tapecon to start a project or for questions related to application engineering, printing, converting, and assembly processes for medical, electronics, and industrial applications.

Confidence Through Better Product Solutions

At Tapecon, we are able to combine our knowledge, capabilities, and service to create a wide range of products custom-tailored to fit your needs, and we have been doing it since 1919. Tapecon is a trusted provider to OEMs of advanced manufacturing of prototypes, components, assemblies, and full production services involving custom materials converting and specialized application printing.

Let's Connect

Use this form to inquire about a project or submit a question. Upon submission, someone from our team will follow-up with you as soon as possible, but always within 1 business day.

Contact Tapecon for questions related to application engineering, printing, converting, and assembly processes for medical, electronic, and industrial applications.

Contact Information

701 Seneca Street

Suite 255

Buffalo, NY 14210

Tel: (716) 854-1322

Tel: (800) 333-2407

Fax: (716) 854-1320

Visitor Entrance

315 Larkin Street

Buffalo, NY 14210

What Our Clients Say

"Tapecon has provided us unmatched support and dedication in developing materials for our growing product lines. We have worked with Tapecon for many years, and the expertise and guidance we have received has been a large contributor to the success of our product lines. We can always rely on expert advice and top quality materials. Thanks for your help in growing our business, it is invaluable to have a partner like Tapecon right here in Western New York."

Product Manager

"Thank you for helping us develop four new products, providing excellent customer service and remaining committed to our vision. I am blown away by the attention and responsiveness I receive from the Tapecon team to the point where I always feel like their most important client."

Product Engineer

"Thank you and everyone at Tapecon for the hospitality and interest in working with us. We were both very impressed with the quality of work that is produced at Tapecon. One thing that I always look for when touring a plant is the level of engagement of the men and women on the floor with visitors. I noticed very clearly that there is ownership and pride among your team and I believe that success only comes when these elements exist coupled with enthusiasm and I was glad to see that yesterday."

President

"I am very glad to have a vendor like your company. I received the automatic shipment notification for the 100 pieces. Once I saw the email, I immediately advised the people involved in order to import the part today. I am very glad to have a vendor like your company."

Purchasing Manager

Recent Articles

We regularly publish content to serve our fellow colleagues in the advanced manufacturing industry.

26Jan

How a Label Estimator Helps You Save Time and Money Before You Ever Request a Quote

.png)

08Jan

Traceability Made Easy: Built-In Serialization for a Clean Device History

19Dec

Driving Innovation Through Collaboration: Why 3M Solutions Seminars Matter

05Dec

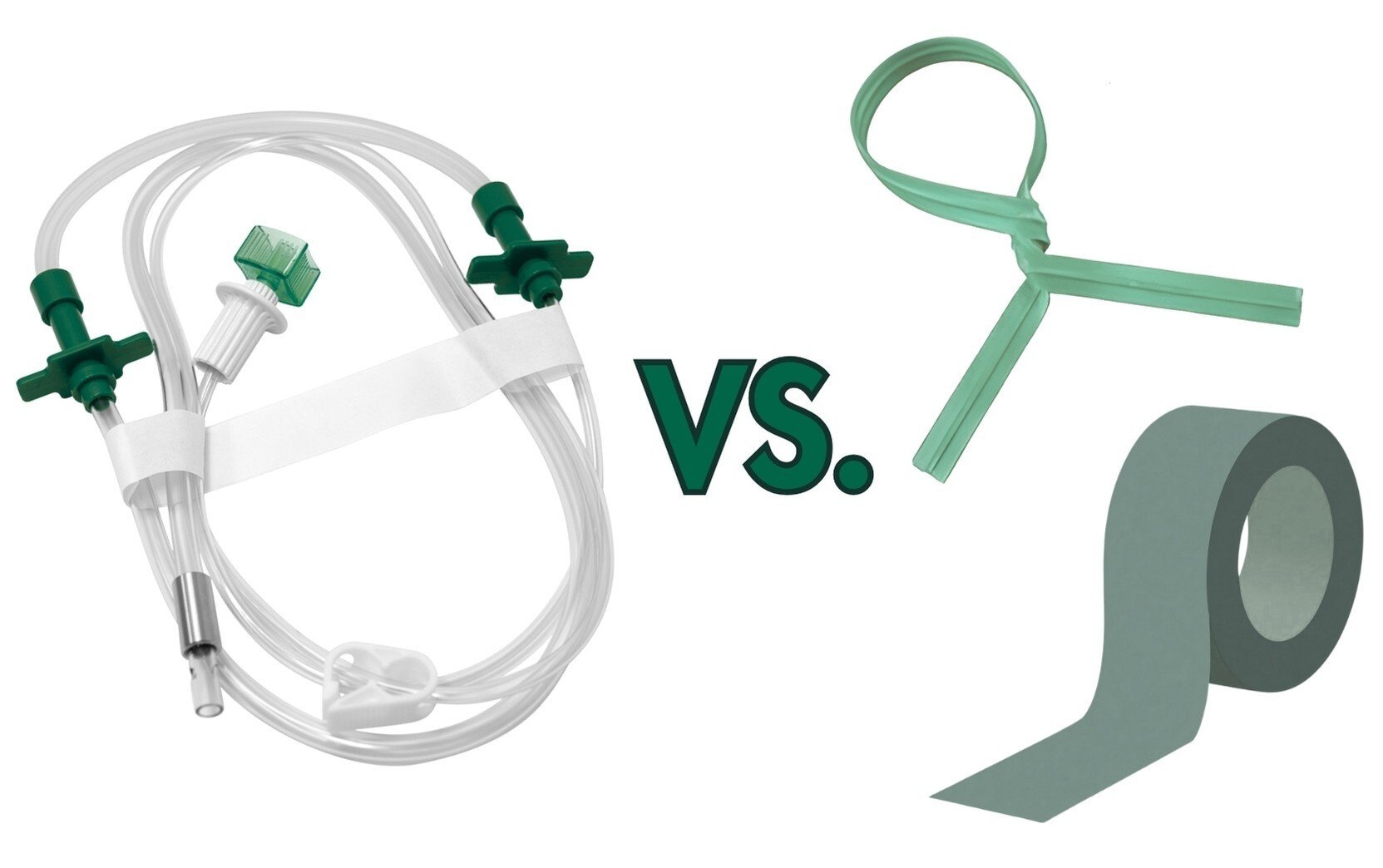

How Ryandra™ Cohesive Tape Outperforms Adhesive Tape and Twist Ties in Medical Tubeset Packaging

.png)

20Nov

How EMI/RFI Shielding Can Lower Total Product Costs Over Its Lifecycle

.png)

07Nov

7 Real-World Ways Printed Chemical Indicators Improve Product Safety and Performance