Design to Delivery Capabilities

Tapecon partners closely with OEMs for outsourced manufacturing of medical devices and of components for medical diagnostic and monitoring equipment. Our clean room, sterile handling capabilities, and experience in functional inks, materials, &packaging provides new outsource options for medical manufacturers. Our ISO 13485 certification, FDA Registration, and our long list of prominent OEM customers serve as a testament to our knowledge and understanding of the critical industry guidelines and requirements.

Conceptualization & Application

Concept brainstorming

Requirements specification

Exploring alternatives

Materials selection

Prototyping

Supplier qualification

Engineering & Manufacturing

Detailed technical specification

CAD drawings

Value engineering

Design for manufacturability

Preproduction samples

Assembly

Supply Chain Services

Customized packaging and labeling

Order cost minimization

Private labeling

Traceability tracking

Drop shipment

Lot customization

Kanban & inventory management

Turnkey outsourced Product Manufacturing

Low to high volume, Tapecon will work closely with you to produce either your engineered design or to assist in taking your product concept through specification, design, engineering to final production and shipment. Our expertise in materials, adhesives and converting techniques for medical products enable us to help you meet your budget and shipment goals.

Medical Materials Expertise

Selecting the right materials for a product is key to meeting goals for performance, reliability, safety, functionality, and cost. Tapecon can advise, sample and test to ensure that the design meets the application requirements. For stick to skin wearable applications, we can work with ISO 10993 biocompatible materials.

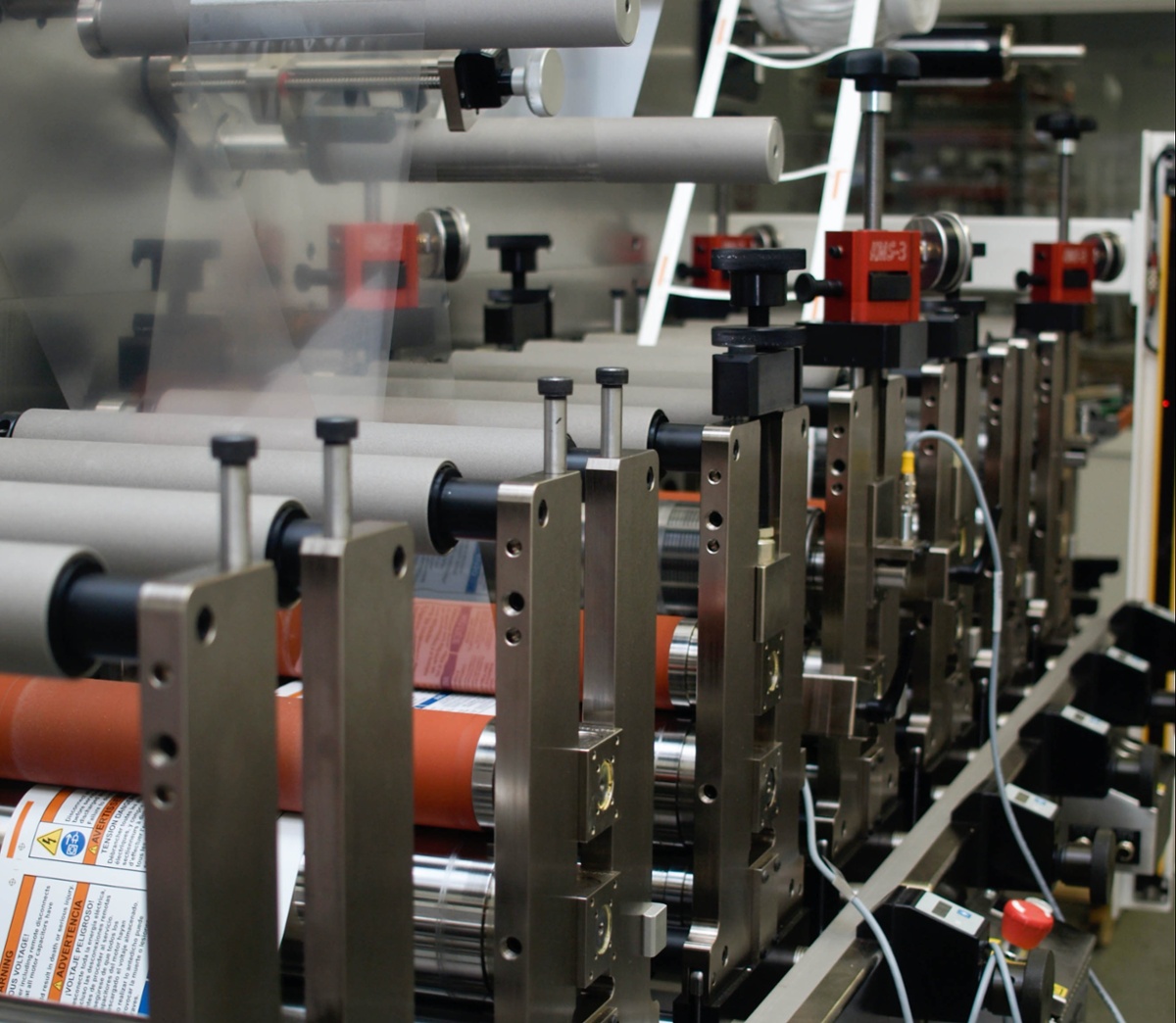

Medical Converting

- Tight tolerance precision die-cutting of complex and simple shapes.

- Laser systems for cutting, perforating, seaming, etching, welding, marking, and engraving.

- Precision slitting, rewinding, web cleaning

- Laminating, including multi-layer laminations

- Custom slitting and rewinding

- Consigned material conversion

Medical Printing

Printed Indicators

Tapecon expertise in applying chemistries to substrates enables us to print and coat with functional inks for sensing and measurement. We can work with your proprietary formulations or work with our trusted suppliers to identify the appropriate chemistry for your project.

Wearables

At Tapecon, we work closely with your team to recommend adhesives and materials to maximize your product’s reliability, performance, and safety. With a wide variety of printing and converting capabilities at our disposal, we can customize skin tapes and patches to your precise needs.

Label, Package and Graphics

We can advise on the best substrates, adhesives, and lamination techniques, and then apply printing technology to meet the application requirements on cleanability, durability, chemical resistance, and branding. Tapecon has equipment for low volume digital or high volume jobs

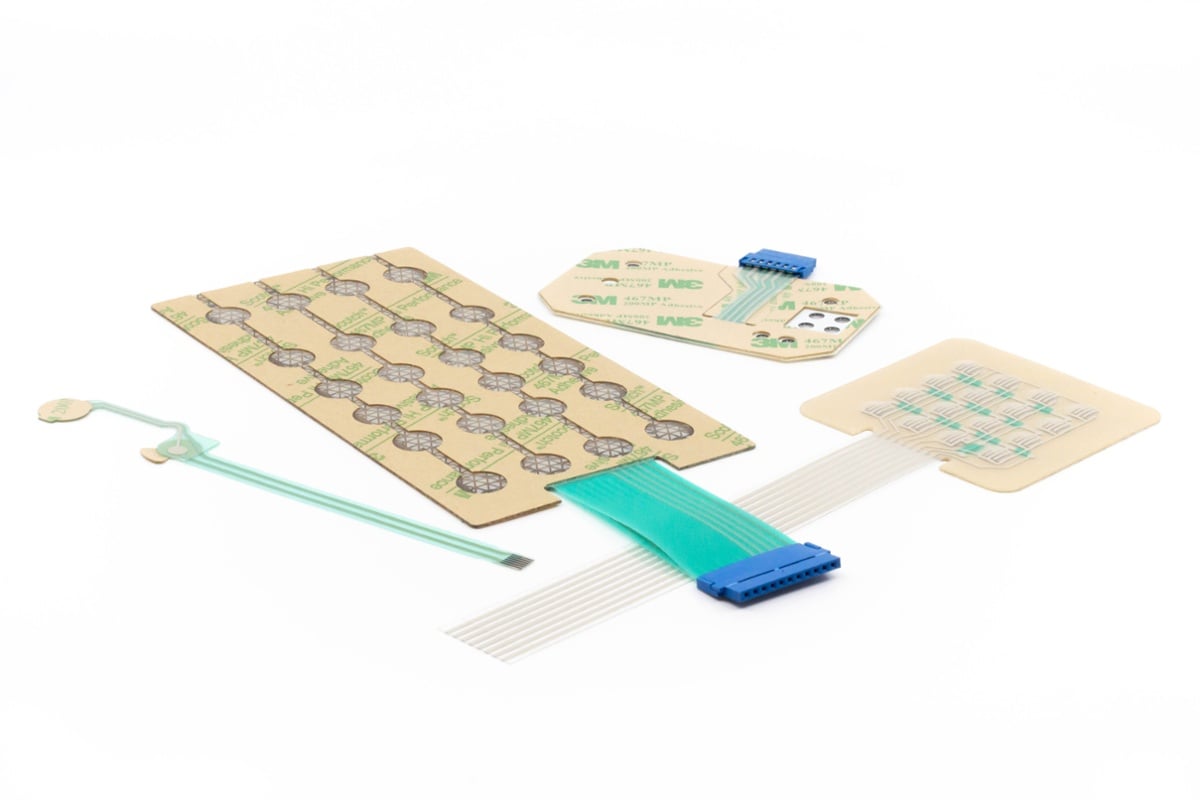

Printed Electronics

Tapecon has expertise in Flexible and Printed Electronics enabling us to print and convert electronic components.

Let's Get Started

To learn more about partnering with Tapecon, fill out this short form and a Tapecon representative will follow up with you as quickly as possible. As a fifth-generation family business, we pride ourselves on being trusted manufacturing partners for our clients, and we look forward to working with you.

What Our Clients Say

"Tapecon reviewed our proposed design and gave us prompt professional assistance."

Research Engineer

"Great interaction and professionalism for a start-up product component."

Supply Chain Consultant

"Good communication from customer service."

Purchasing Manager

"What my company appreciates most is their flexibility should we need an order or a partial sooner than the due date at the time of order submission. These attributes make them stand out in their industry!"

Senior Buyer

Recent Articles

We regularly publish content to serve our fellow colleagues in the advanced manufacturing industry.

.png)