What are labels and decals?

Labels and decals are printed graphics that are adhered to products or packaging. Since these elements are intended to be both visually appealing and convey important information, careful consideration must be made to ensure color accuracy, legibility, and durability.

With over 100 years of experience, Tapecon has earned a reputation as a trusted leader in industrial printing. Our high-quality labels and decals can be found on leading products around the world. Our expert team can recommend the ideal product construction, printing method, and finishing techniques for your needs.

Uses for Labels & Decals

Whether for brand identify, decoration, instructions, safety, or regulatory compliance, printed labels and decals are used on countless products.

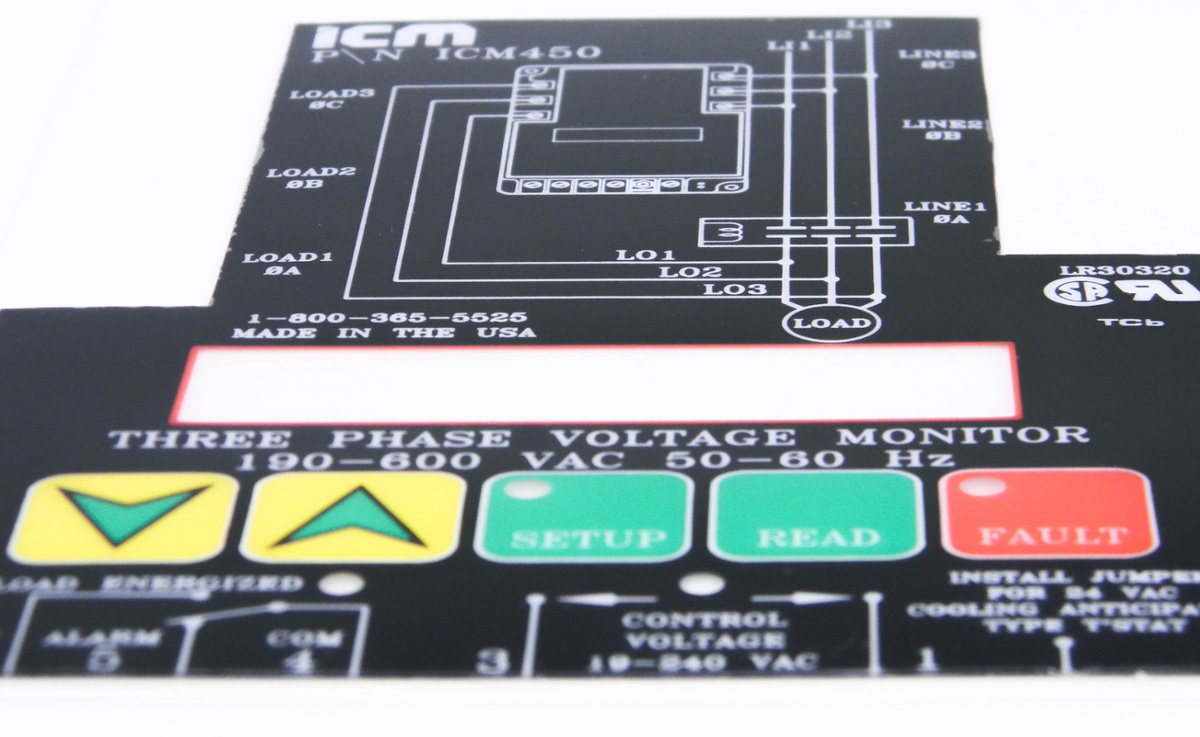

Equipment

Warning labels

Product identification

Medical devices and packaging

GET YOUR CUSTOM LABEL ESTIMATE IN JUST FIVE QUESTIONS

The Tapecon Label Estimator is a new resource developed by identifying the five biggest factors that play into label pricing. By taking this quiz, you'll be able to instantly get an idea of what your label project's pricing may look like, without the commitment of an inquiry.

The right printing for the job

Not all labels and decals are created equal. That’s why Tapecon offers multiple printing methods, including various digital methods as well as screen, and flexographic. Our printing technicians can recommend the best route based on your product, usage, and specifications.

Extensive features, unlimited possibilities

Our vast printing capabilities allow you to push the envelope of your label and decal design, and truly distinguish your product from the competition. If you can imagine it, odds are we have a way to print and produce it.

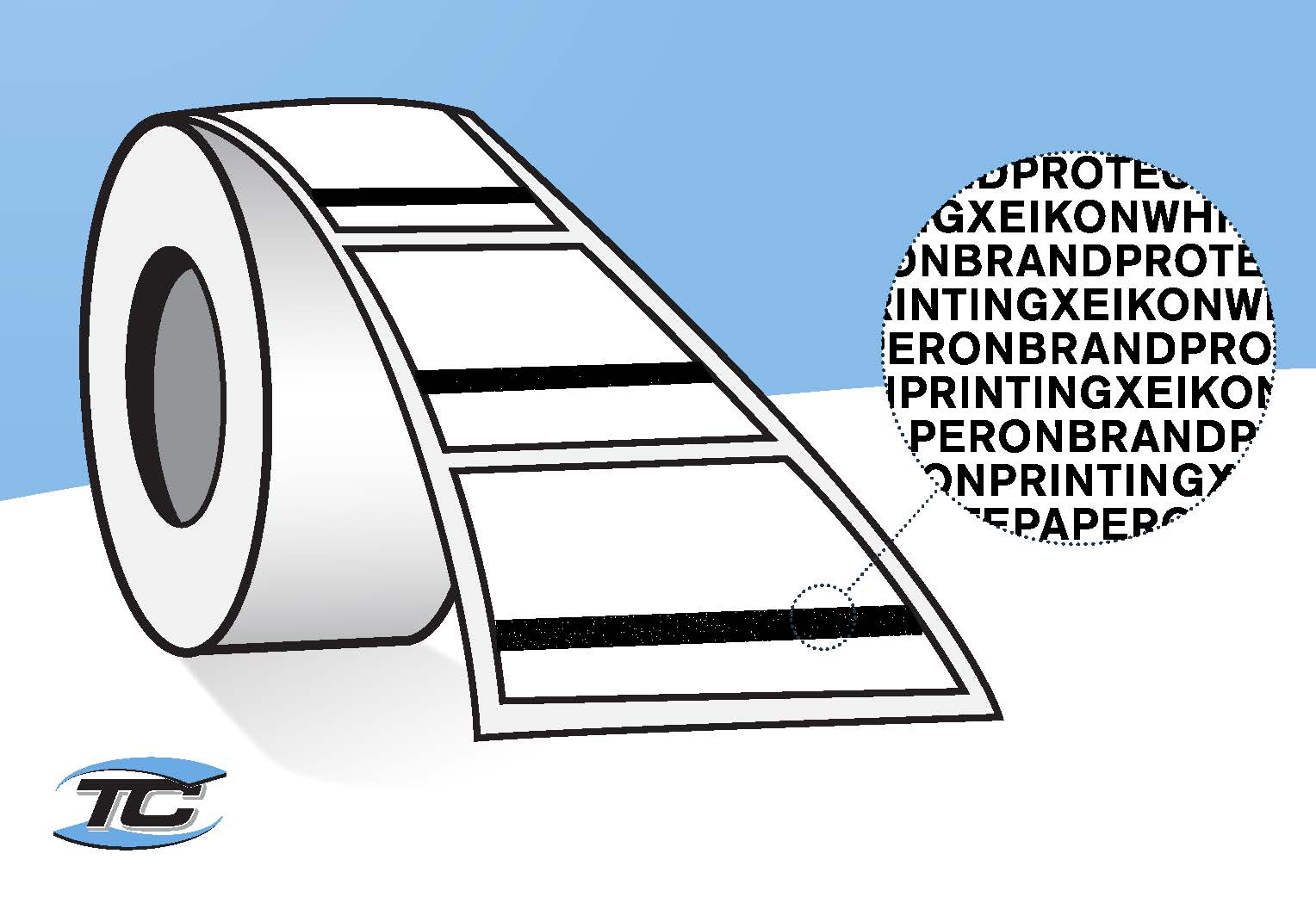

Packaging and Labels that Enhance Security

Looking for a way to prevent unlicensed manufacturing and distribution of your product? It’s an unfortunate truth that companies today need to protect their intellectual property and bottom line.

While designing and producing your packaging label, Tapecon can include a wide range of effective printed security features.

- Microtext: Text is added in a font size so small it's nearly invisible to the naked eye.

- Guilloches: Special, complex line drawings with irregular, complex shapes and patterns that are extremely difficult to copy.

- Variable imaging: Elements are added for authentication, sterilization, barcodes and randomly placed micro-dots.

- Raised images and illustrations: A tactile feature can be introduced to printing products that creates another dimension of brand security.

- Security substrates: Options include thermo- and UV-sensitive substrates, reactive anti-fraud chemicals, watermarks holograms, embedded threads, and foils.

- Clear toner: Adds text, messages, or shapes that are visible only under UV light.

Variable Imaging

.jpg)

Barcodes

Microtext

A Smarter Approach

Looking for another level of sophistication in label monitoring technology? Make sure to check out our Smart Solutions Center and see how Tapecon's capabilities in smart labeling can best serve you!

Applications and Services

If your design calls for a label or decal, you may also be interested in learning about other ways Tapecon can improve your product.

Let's Get Started

To learn more about partnering with Tapecon, fill out this short form and a Tapecon representative will follow up with you as quickly as possible. As a fifth-generation family business, we pride ourselves on being trusted manufacturing partners for our clients, and we look forward to working with you.

What Our Clients Say

"Tapecon reviewed our proposed design and gave us prompt professional assistance."

Research Engineer

"Great interaction and professionalism for a start-up product component."

Supply Chain Consultant

"Good communication from customer service."

Purchasing Manager

"What my company appreciates most is their flexibility should we need an order or a partial sooner than the due date at the time of order submission. These attributes make them stand out in their industry!"

Senior Buyer

Recent Articles

We regularly publish content to serve our fellow colleagues in the advanced manufacturing industry.

.png)

.png)