CASE STUDIES

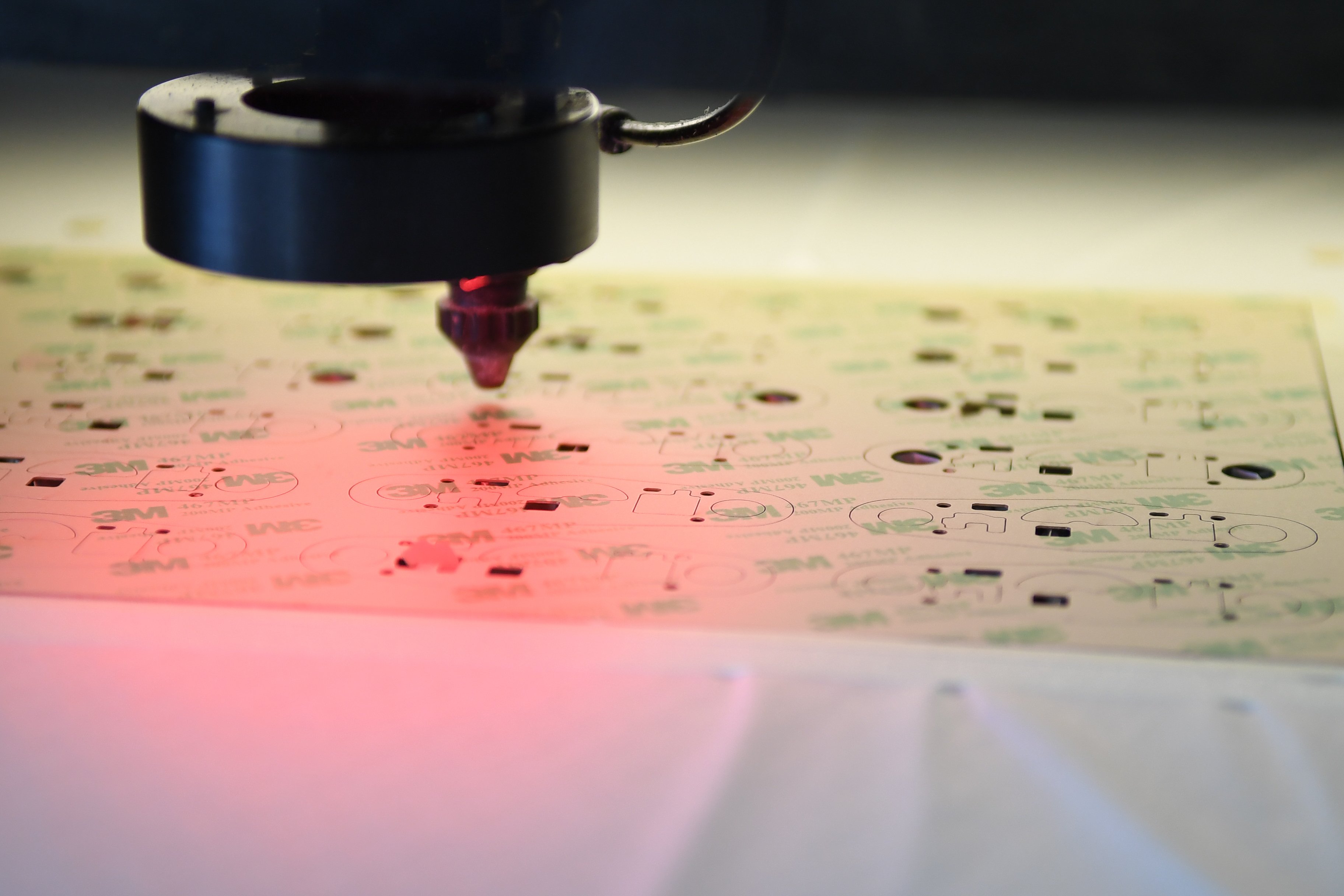

Printing. Converting. Complex Problem Solving.

We solve the application challenges of our customers to improve their products. We combine science and application expertise to deliver solutions for our customers. Read about the real-life success stories we've helped our customers achieve.

BUSINESS PROCESS OUTSOURCING OF PRINTING AND CONVERTING IN ACTION

Recent Articles

We regularly publish content to serve our fellow colleagues in the advanced manufacturing industry.

.png)