Solutions for Shielding Membrane Switches from Interference

Written by Casey Cephas

Murphy’s law tells us that anything that can go wrong will go wrong. While this isn’t necessarily a scientific law, it’s something that product designers must keep in mind. When it comes to electronics, interference is always a concern, especially in a compact component such as a membrane switch. Fortunately, there are simple solutions for shielding and blocking various forms of interference, so they don’t impact the product or user.

Electromagnetic interference and radio frequency interference

Electromagnetic interference (EMI) and radio frequency interference (RFI) are related – both involving electrical noise – but they are distinct issues and affect devices differently.

- EMI is high-frequency noise from the device that can interfere with other components

- RFI is interference coming from external devices and has a longer wavelength

What EMI and RFI have in common is that they degrade circuits – causing data loss or device failure.

Electrostatic discharge

Electrostatic discharge (ESD) is a short but intense flow of electricity when two electronically charged objects come in contact. In a device with a membrane switch interface, this can happen when the user presses down a button. As you can imagine, ESD can damage sensitive circuitry and other components within the device.

Solutions for shielding interference

Not every membrane switch requires shielding for EMI, RFI, or ESD. In some cases, the graphic overlay provides enough of a buffer to protect the internal components. However, for various reasons – including application, environment, regulations, and more – additional shielding is often warranted.

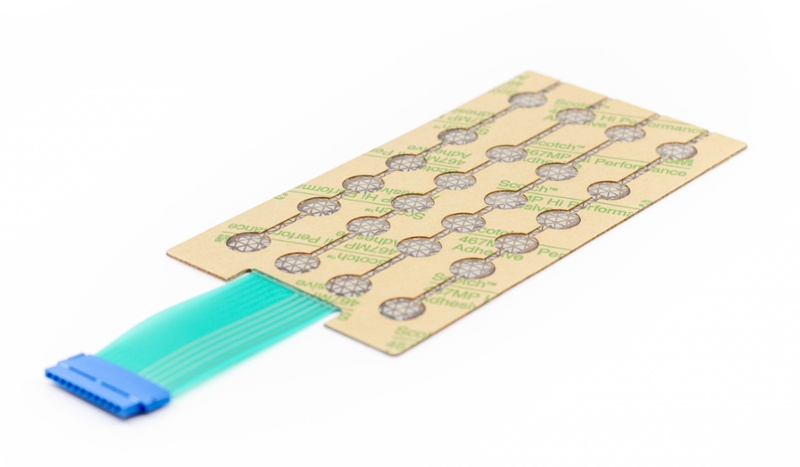

There are a few shielding methods for membrane switches, including foils, films, printed screens, gaskets, etc. Shielding components are integrated into the membrane switch’s construction, often below the graphic overlay (also known as the faceplate).

Manufacturing shielding components for membrane switches

There’s no one-size-fits-all approach for protecting membrane switches from interference. At Tapecon, we can provide design consultation, materials selection, and testing to ensure you have the optimal shielding solution to protect your product and user. As a full-service custom converter, we have the experience and capabilities to handle every aspect of your membrane switch production.

Get started with membrane switches

At Tapecon, we have over 100 years of experience helping customers solve their complex product challenges. Learn more about our membrane switch applications.