Flexible Printed Electronics

Tapecon provides outsourced converting, printing and manufacturing for OEM Medical and Industrial applications.

Accelerate Innovation and Production

Focus more of your attention and budget on your core competencies and leave the production details to us. Using our experience with materials and printing and converting processes, we can avoid potential roadblocks, offer design improvements, and get your product to market quicker.

IMPROVED VALIDATION AND REDUCED RISK

We understand the regulation challenges you face when developing a new product. Our quality and compliance team can write and execute process validation protocols to meet your needs, mitigate your risk, and keep your product launch on schedule.

A Collaborative Approach

We strive to be a trusted partner in your success – not just a transactional vendor. We can provide the most value when we collaborate early and often in your product development process. At all stages of our engagement, we look for ways to improve the function and manufacturing efficiency of your product.

Tapecon Applications & Capabilities

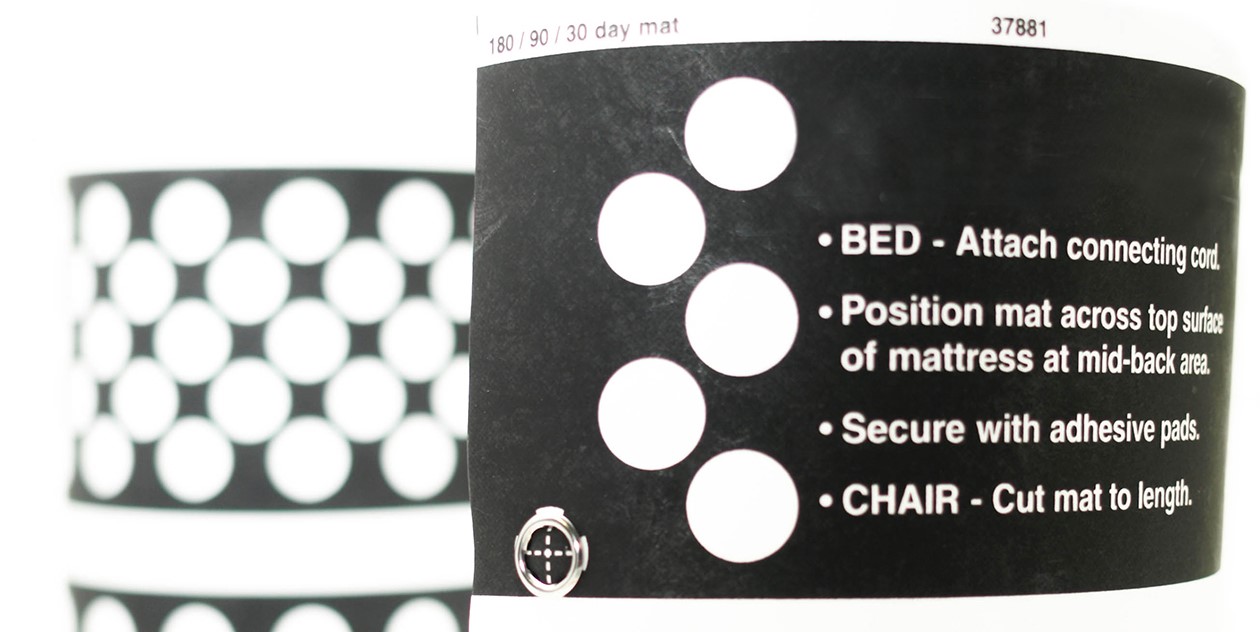

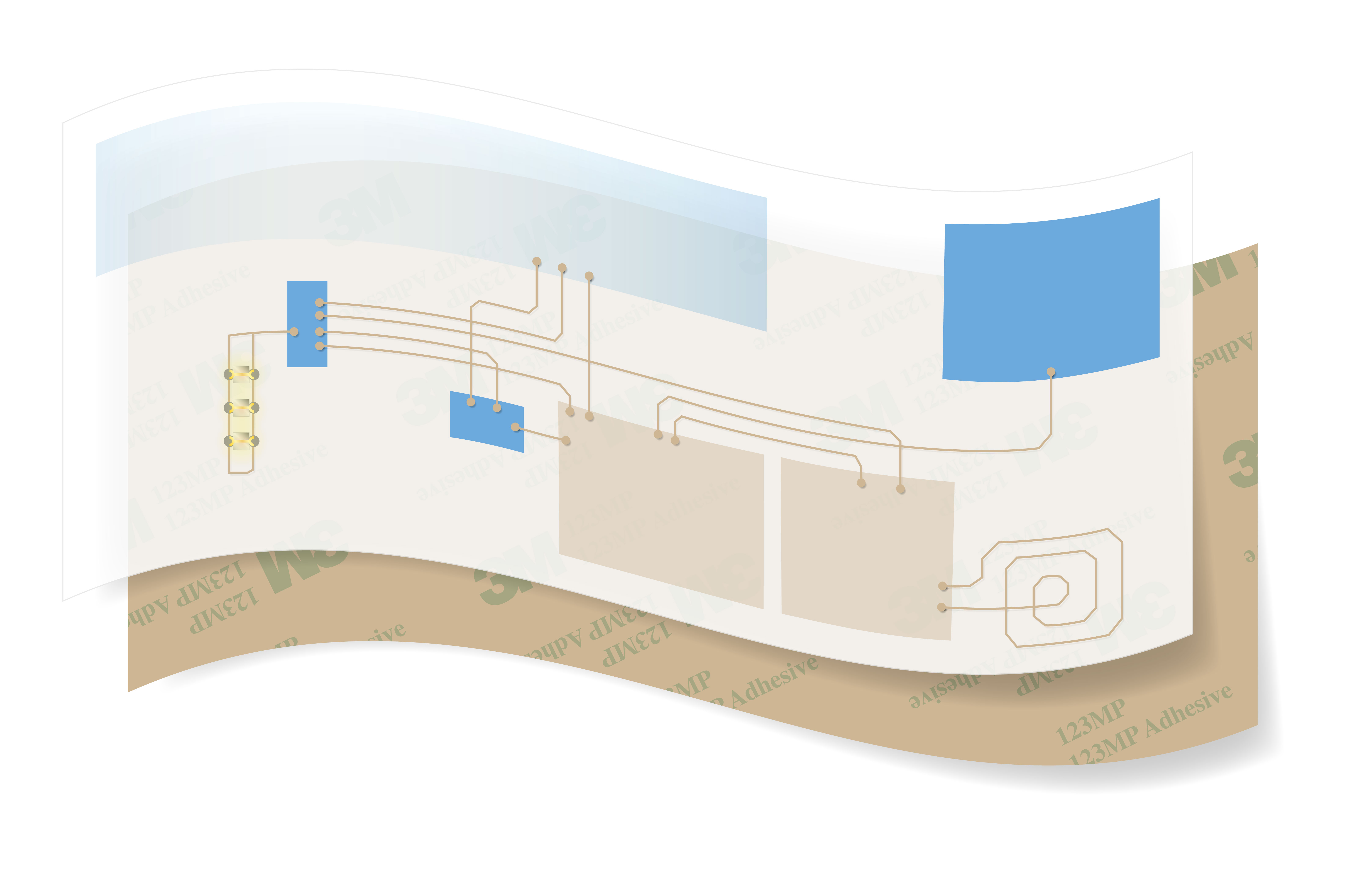

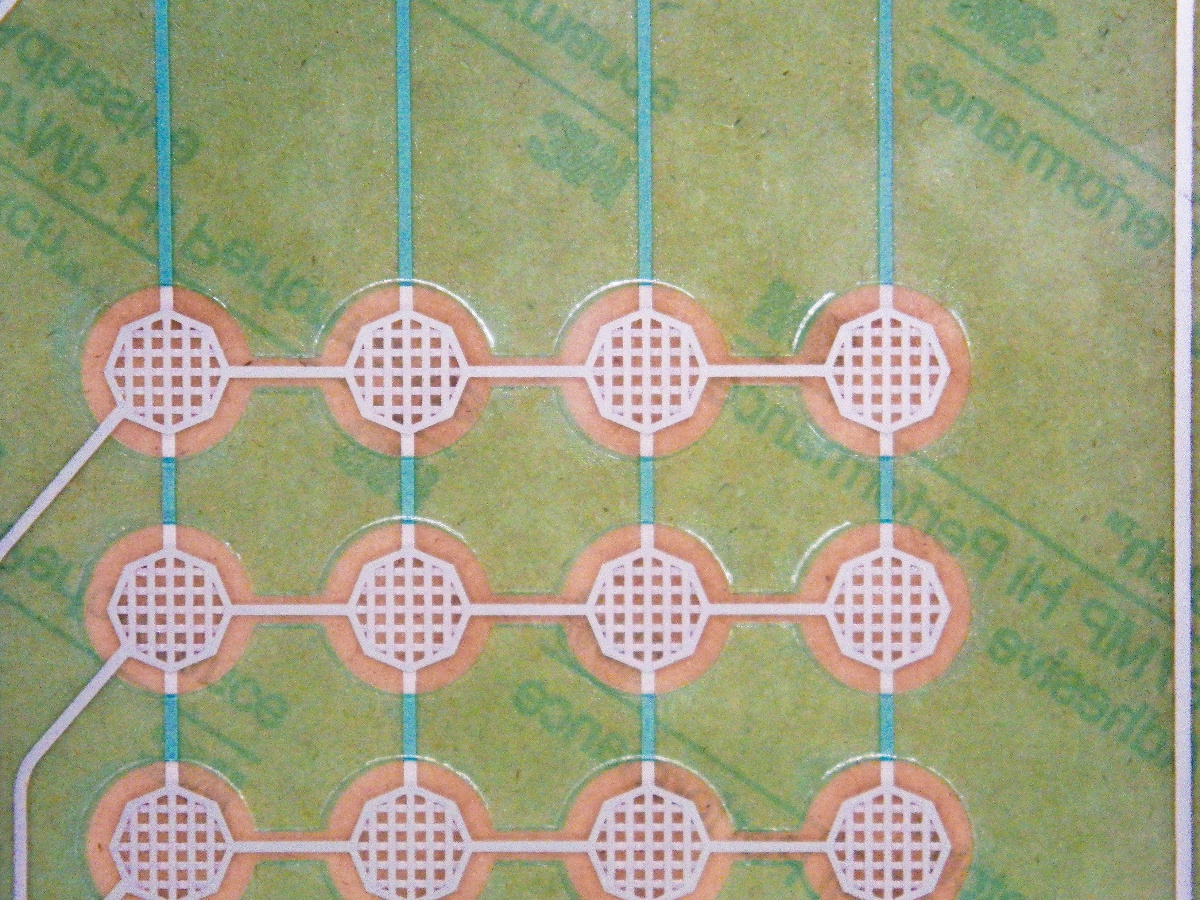

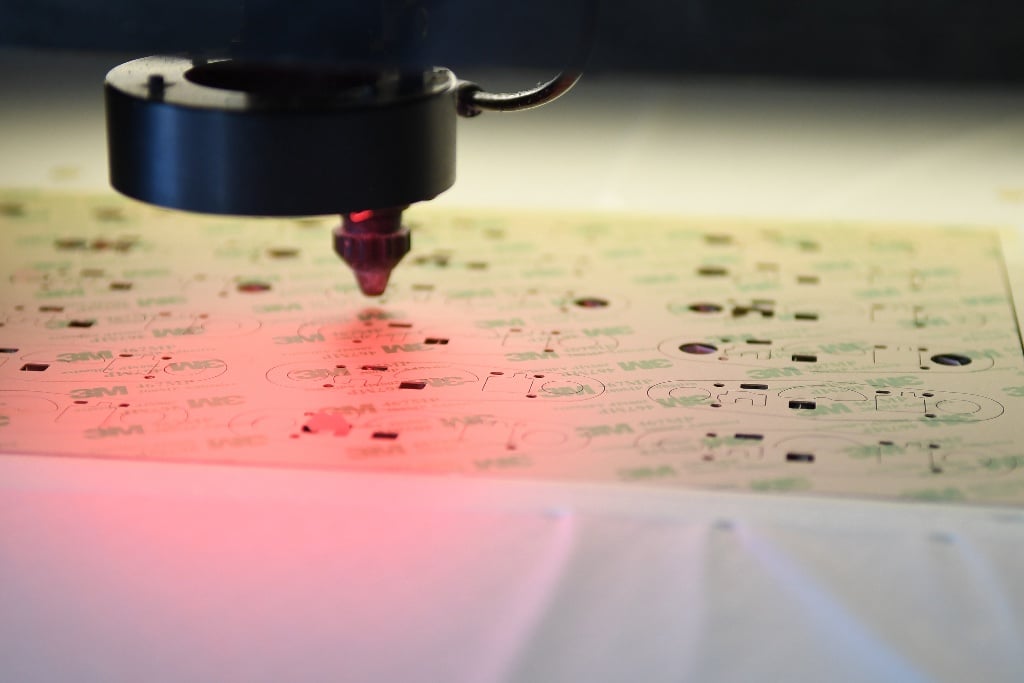

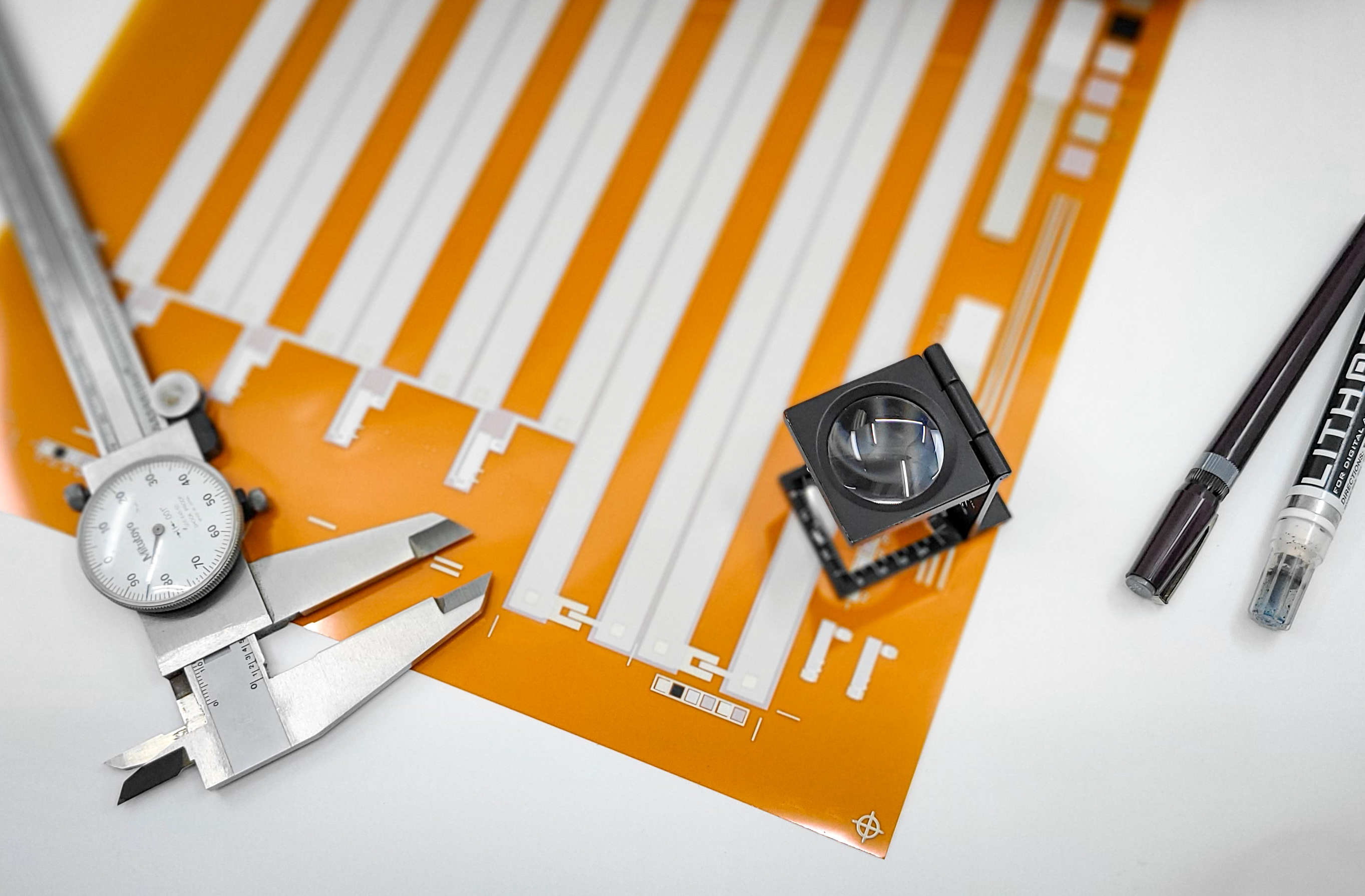

Flexible Printed Electronics

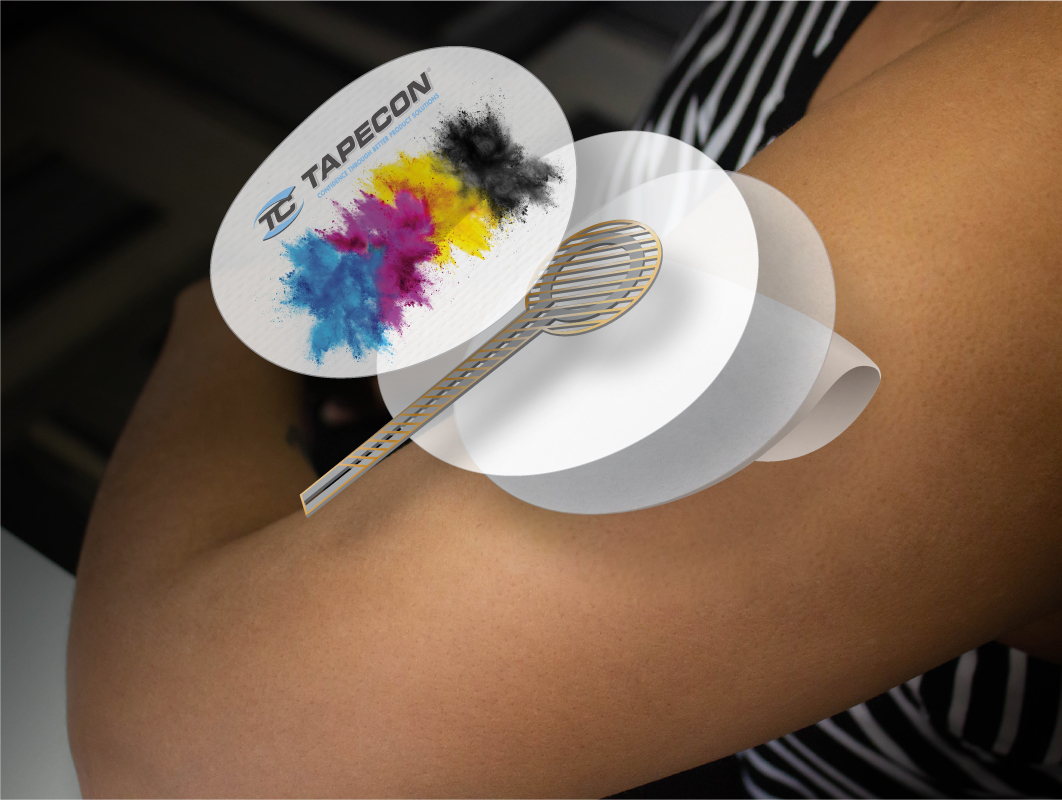

Wearables

Printed Indicators

Durable Printing & Coating

Material Converting

Engineering Services

Technology & Design Support Stories

Tapecon has helped customers and university partners with design support and production services to help accelerate technology and products.

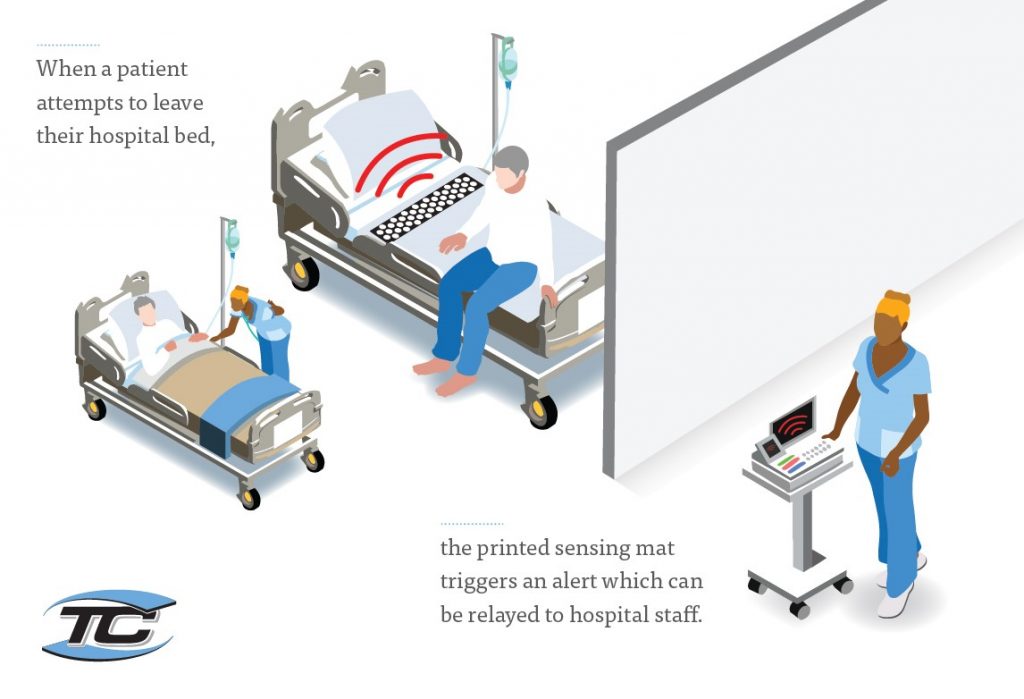

Torque Sensor

Tapecon worked with GE Global Research to design a printed, flexible option to replace a rigid torque sensor. Using our expertise in printed electronics processes and materials, Tapecon was able to manufacture a more accurate & lighter weight sensor that was a lower cost compared to etched copper options.

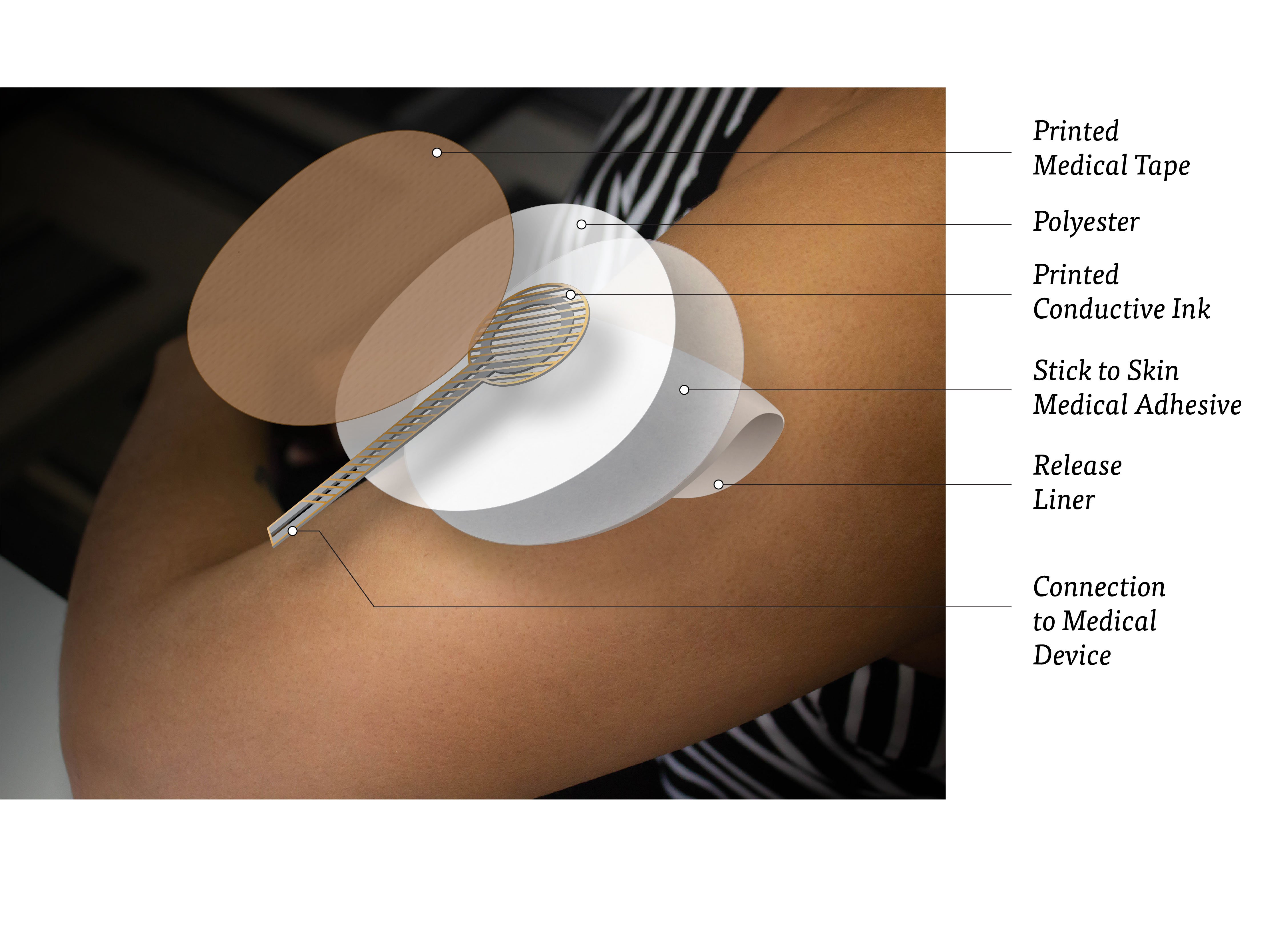

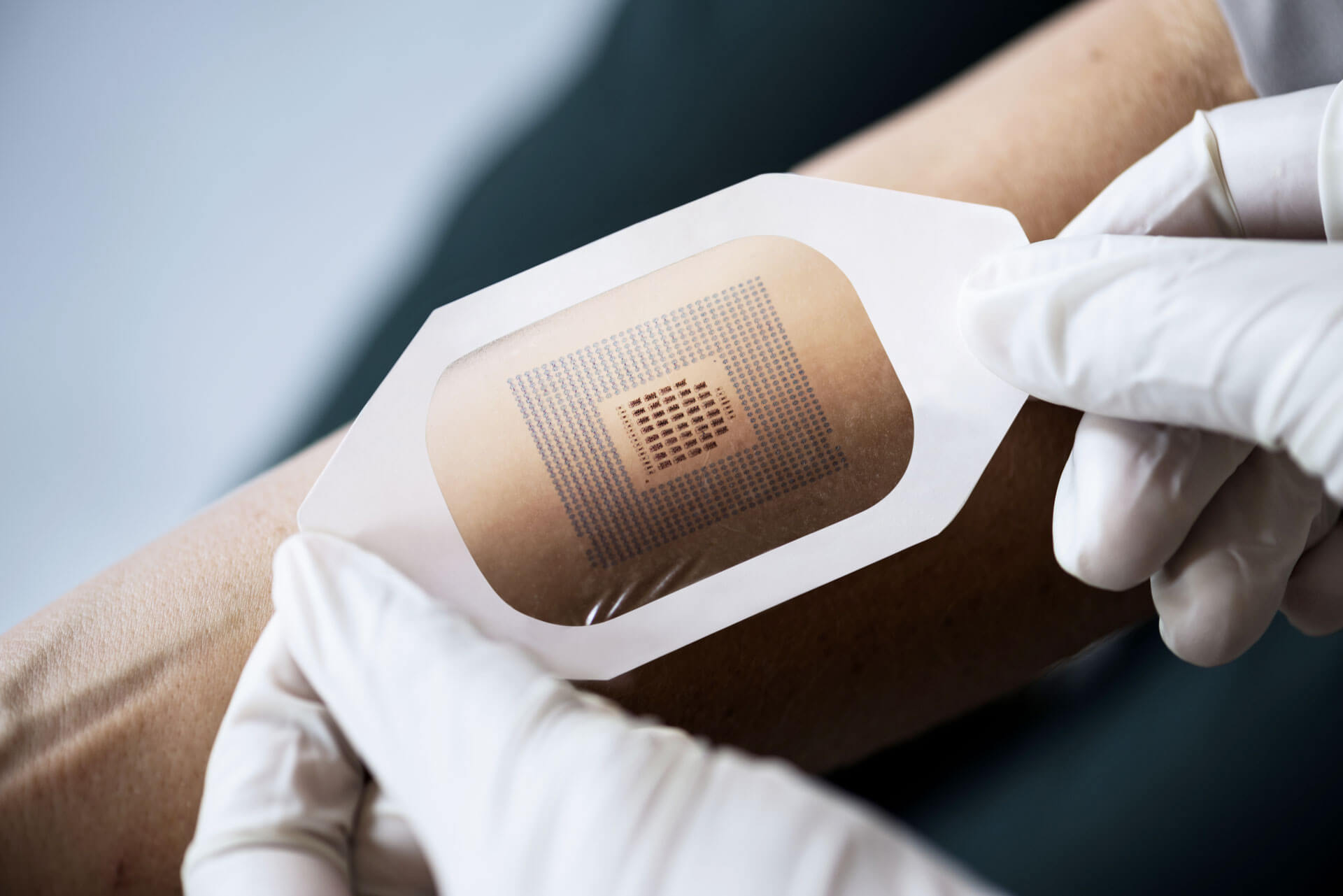

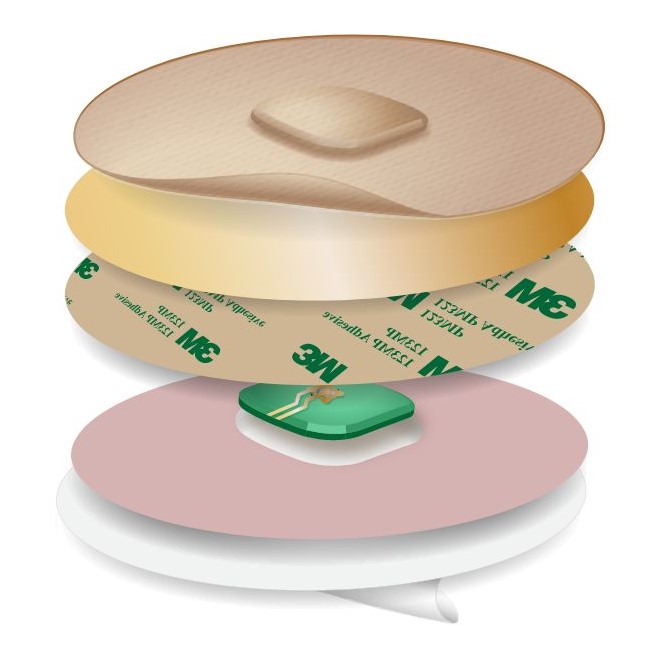

Wearable Temperature Sensor

Tapecon partnered with Binghamton University to prove FHE capability, viability and manufacturability of a wearable temperature sensor. The project involved updated design for manufacturing, printing conductive inks, placing components and adding a wearable stick to skin substrate with top graphics.

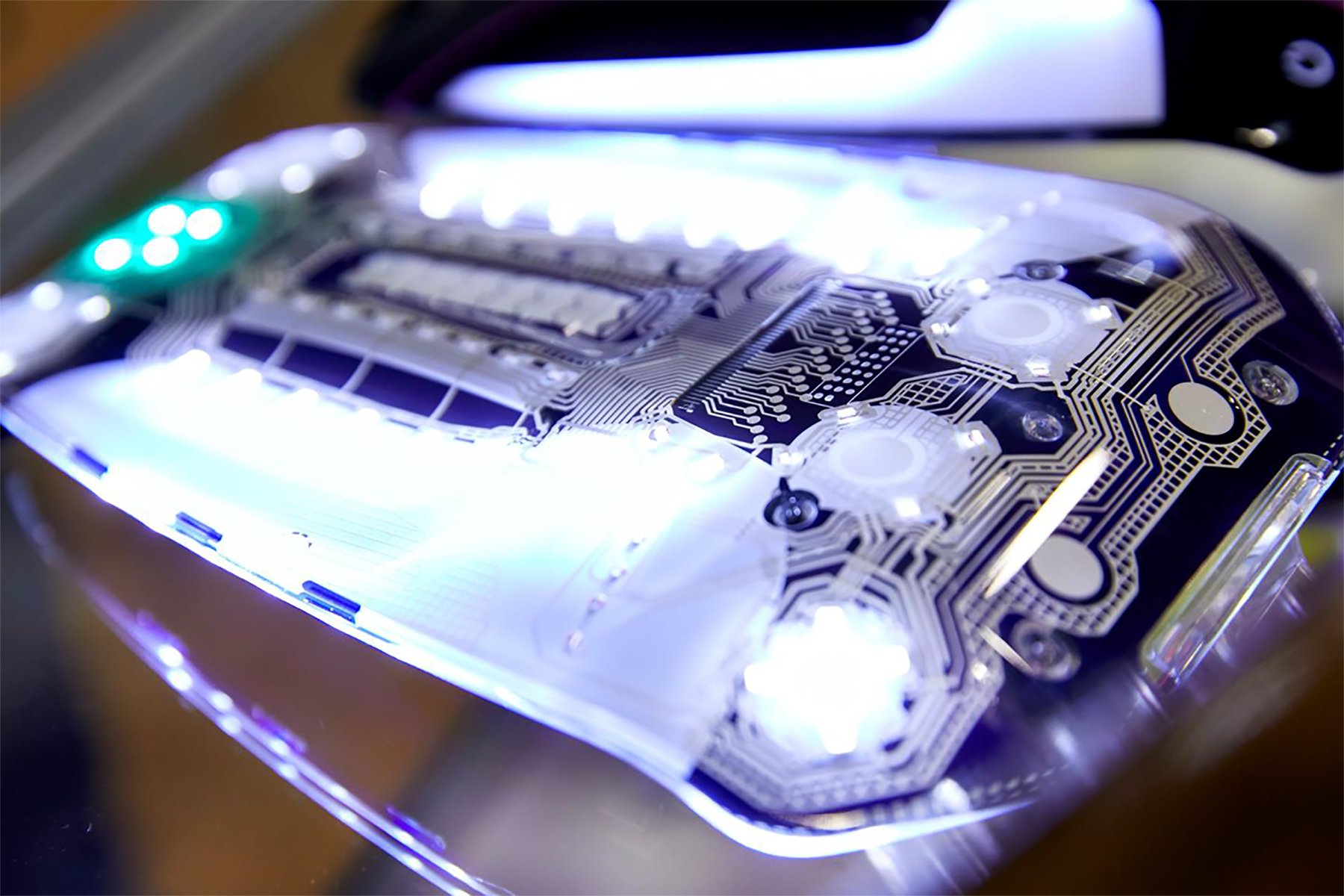

Wearable Monitor Circuits

Tapecon worked with GE Global Research to help build and complete circuits for a wearable monitor. Tapecon's engineering team became an extension of the GE Research project team and was able to work through design iterations to provide optimal prototypes. Ultimately, Tapecon was able to help meet quick deadlines for prototypes and create designs that were ready for scalable manufacturing. Including a manufacturing partner in the early stages allow the process to move more efficiently.

About Tapecon

For over 100 years, Tapecon has partnered with product teams to develop, scale, and deliver better products through responsive and reliable printing, converting, and advanced manufacturing.

Tapecon provides expertise in specialized printing and converting, printed flexible electronics, and contract manufacturing of disposable devices for medical and industrial markets. Established in 1919, Tapecon is a 5-generation, family-owned business based in Buffalo, New York.

Quality & Compliance

Tapecon ensures that we meet your demanding product specifications through our quality management system and a wide assortment of tools and equipment.

Helpful Resources

We regularly publish content to serve our fellow colleagues in the advanced manufacturing industry.

LET'S CONNECT

Use this form to inquire about a project or submit a question. Upon submission, someone from our team will follow-up with you as soon as possible, but always within 1 business day.