It’s a big, messy world out there. When you think about how far our products travel, how often they’re handled, and the environmental conditions they’re exposed to, you begin to understand how vital sterilization processes are to medical, industrial, and other industries that can impact our health.

Thankfully, there’s a simple, cost-effective solution to verifying sterilization without constant oversight or high-tech equipment. Read on to learn about printed indicators and the different sterilization methods available.

What are printed indicators used for?

Printed indicators are printed applications featuring functional ink that react to specific biological, chemical, or environmental changes. Essentially, when the indicator is exposed to the variable, the ink changes colors in a dramatic fashion (such as from pink to brown). This process makes it easy to confirm the presence of a factor or detect contamination or tampering. Indicators can be printed directly on the product, packaging, or on a separate label.

Printed indicators have many uses and can enhance a wide range of products. But one popular and necessary function is sterilization.

Methods for sterilization

At Tapecon, we’re often asked, “What’s the best sterilization method?” The truth is that it depends on your application and the type of materials you’re using. Here are six common sterilization methods and the pros (and some cons) for each.

- Steam – With steam sterilization, the item is placed in a chamber, such as an Autoclave, and exposed to water vapor and heat. Steam is a tried-and-true sterilization method, economical, and often used in medical applications.

- Ethylene oxide (EO) – EO is typically used when the materials to be sterilized are sensitive to heat, moisture, or other chemicals. Since EO is a universal and effective sterilant, it can be used in various medical applications.

- Hydrogen peroxide – Vaporized hydrogen peroxide can sterilize products at a lower process temperature than steam. This is a newer sterilization method; however, it may cause some materials to become brittle, so compatibility testing is essential before selecting.

- Gamma irradiation – Ionized radiation is a very effective sterilization method and can even penetrate most packaging materials to kill organisms on the interior product surface.

- Formaldehyde – Often used for items that are sensitive to high temperatures or moisture, vaporized formaldehyde gas can be used for sterilization in a low-temperature process.

- Dry heat – For products that can handle high temperatures but are prone to moisture damage, dry heat for a prolonged time can be a suitable sterilization method. Benefits include a simple process to implement and low operating costs.

Classes of printed indicators for sterilization

In addition to the sterilization method, there are also six classifications of sterilization printed indicators based on how they function and the number of variables needed to trigger a color change.

|

Class

|

Category

|

Description and purpose

|

|

1

|

Process indicators

|

Provides visual confirmation of exposure to the sterilization process. Distinguishes between processed and unprocessed units

|

|

2

|

Indicators for specific tests

|

Indicators for specific test procedures, such as the Bowie-Dicks Test.

|

|

3

|

Single-variable indicators

|

Shows exposure to one sterilization method.

|

|

4

|

Multi-variable indicators

|

Shows exposure at specific values for multiple variables.

|

|

5

|

Integrating indicators

|

Designed to react to all critical variables, correlated with biological indicators.

|

|

6

|

Emulating Indicators

|

Designed to react to all critical variables for a specific sterilization cycle.

|

Printing and converting services for sterilization indicator

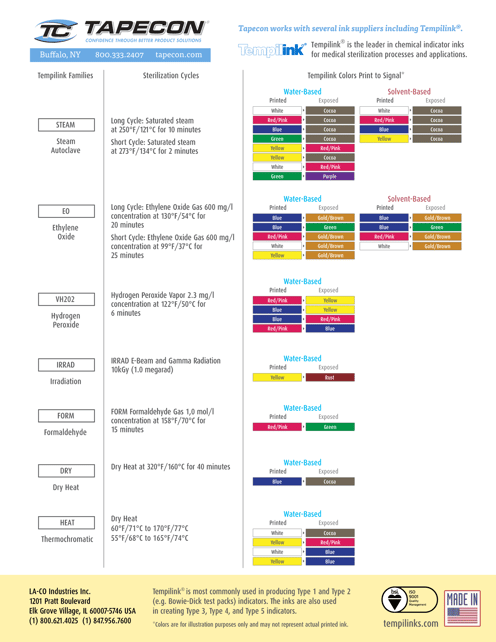

Printed indicators are simple applications but making them isn’t as easy as using your office inkjet printer. At Tapecon, we have extensive experience designing printed indicators and working with functional inks for sterilization (see below chart). We also offer materials converting capabilities to customize your printed indicator to your exact specifications.

Let’s make something great

With over 100 years of manufacturing experience, Tapecon works with product teams to solve challenges, create products, and enhance lives. Learn more about our printed indicator applications.