How Printed Flexible Electronics Are Shaping the Future

Written by Casey Cephas

Human history is marked by inventions that have propelled society forward. As digital technology evolves at a breakneck pace, the role of electronics in our daily lives and industries becomes greater and greater. Developing smaller, light, and more portable devices requires not only out-of-the-box thinking but also cutting-edge materials and manufacturing process.

In this article, we’re talking about how printed flexible electronics are shaping the future, and highlighting exciting technologies and applications available to product designers today.

Why flexible electronics is at a tipping point

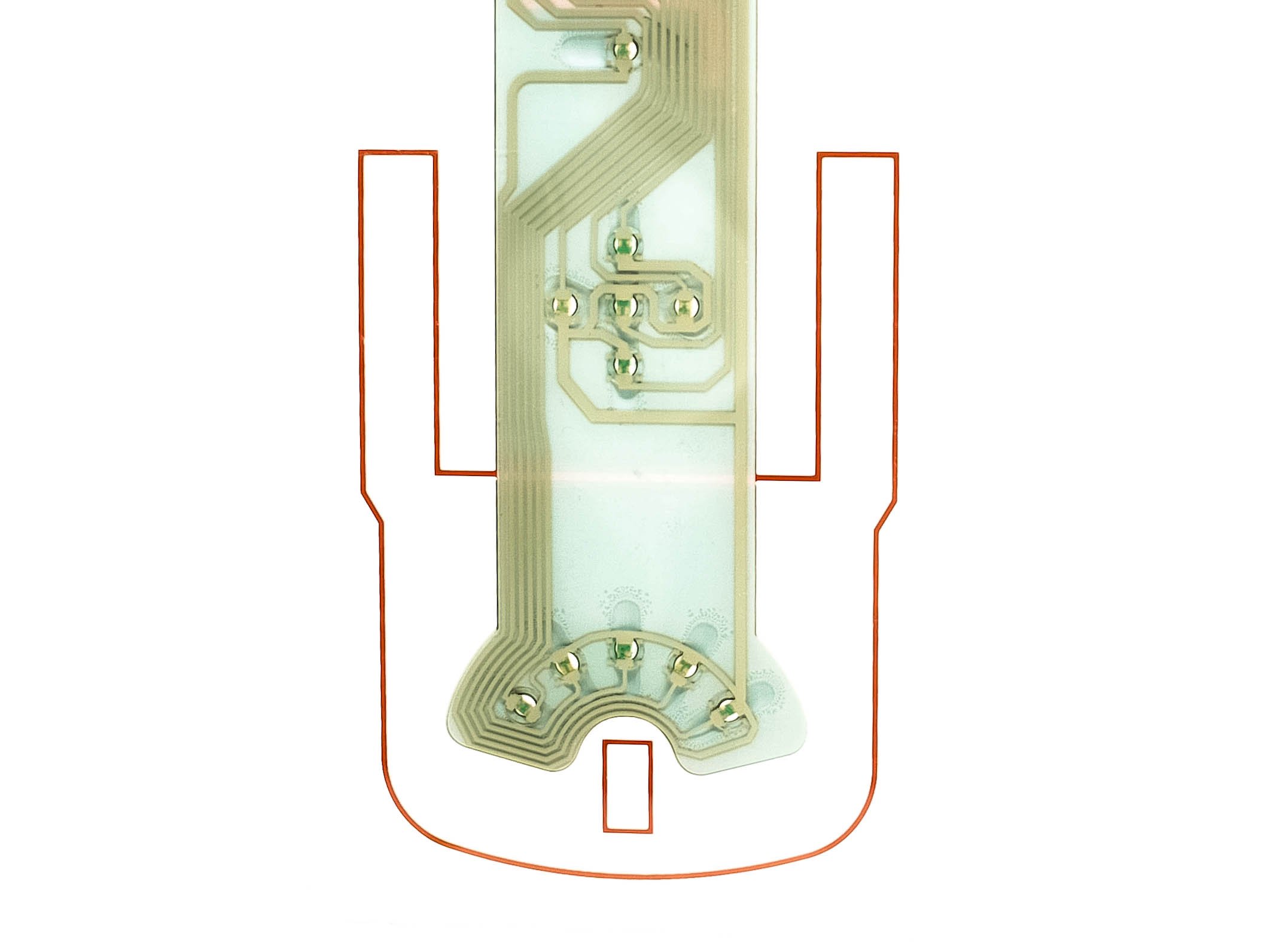

Printed flexible electronics aren’t a brand-new concept – in fact, they’ve been around for a few decades. However, up until recently, there was a significant performance gap between flexible electronics and conventional, rigid electronics. Thanks to advancements in materials science, printing technology, and other additive manufacturing processes, product designers can now leverage flexible electronics’ many benefits without sacrificing capabilities and functionality. Furthermore, you can get the best of both worlds with flexible hybrid electronics (FHE) that combine flexible substrates and low-cost functional ink printing with other traditional components.

What’s especially intriguing about printed flexible electronics is that these solutions aren’t merely an incremental improvement over traditional circuit boards and other components. Yes, flexible electronics can help make an existing product smaller, lighter, and more pliable. But they also open the door to novel form factors and applications. In other words, we’ve only scratched the surface of what’s possible with printed flexible electronics.

Macrotrends with printed flexible electronics

The miniaturization of sensors

When it comes to sensors within an electronics device, bigger is typically not better. Flexible electronics allow sensors to be more compact, accessible, and cost-effective to produce. The proliferation of sensors in new places – and the real-time data they capture – is being leveraged in several industries, including healthcare (biosensors), environmental (gas sensors), automotive (autonomous driving), consumer electronics (fingerprint sensors), and more.

New form factors and innovations

Without the restrictions and limitations of traditional electronic components, designers, engineers, and OEMs can push the envelope with products like never before. Printed flexible electronics provide the opportunity for innovative form factors and product differentiation. Aside from breaking the mold, flexible electronics offer a host of benefits, including smaller devices, improved comfort for users, and lightweighting, just to name a few.

Here are just a few examples of new form factors and innovations made possible by flexible electronics (we’ll cover more exciting applications later in the article).

- E-textiles with flexible, stretchable sensors – this emerging market is expected to reach $2.2Bn by 2028 (IDTechEx)

- Flexible batteries and displays

- 3D printing of structural electronics

Advancements in digital health

Flexible electronics are playing a major role in the technological shift within the healthcare field. Due to our aging population and increasing rates of chronic disease, the medical system needs a reliable, sustainable alternative to traditional hands-on patient monitoring and care. Utilizing flexible electronics, medical devices for remote patient monitoring can be more convenient and comfortable to wear, less invasive, and exceptionally portable. It’s estimated that the market for medical wearables will double from 2019 to 2024, reaching nearly $20 billion.

Wearable or ultra-compact medical devices can be used for a wide variety of point-of-care applications. Biometric sensors can monitor and track heart rate, glucose level, movement, weight, blood pressure, oxygen level, temperature, medication, and much more. This technology currently has the most significant benefit for remote patient monitoring during high-risk cases such as babies and pregnant mothers, the elderly, those with chronic diseases like diabetes, and patients pre- and post-surgery.

As technology advances, we expect that devices with flexible electronics will enhance other healthcare areas, including diagnostics, genetic testing, telemedicine, health analytics, lifestyle tracking, pharmaceutical research, and general wellness.

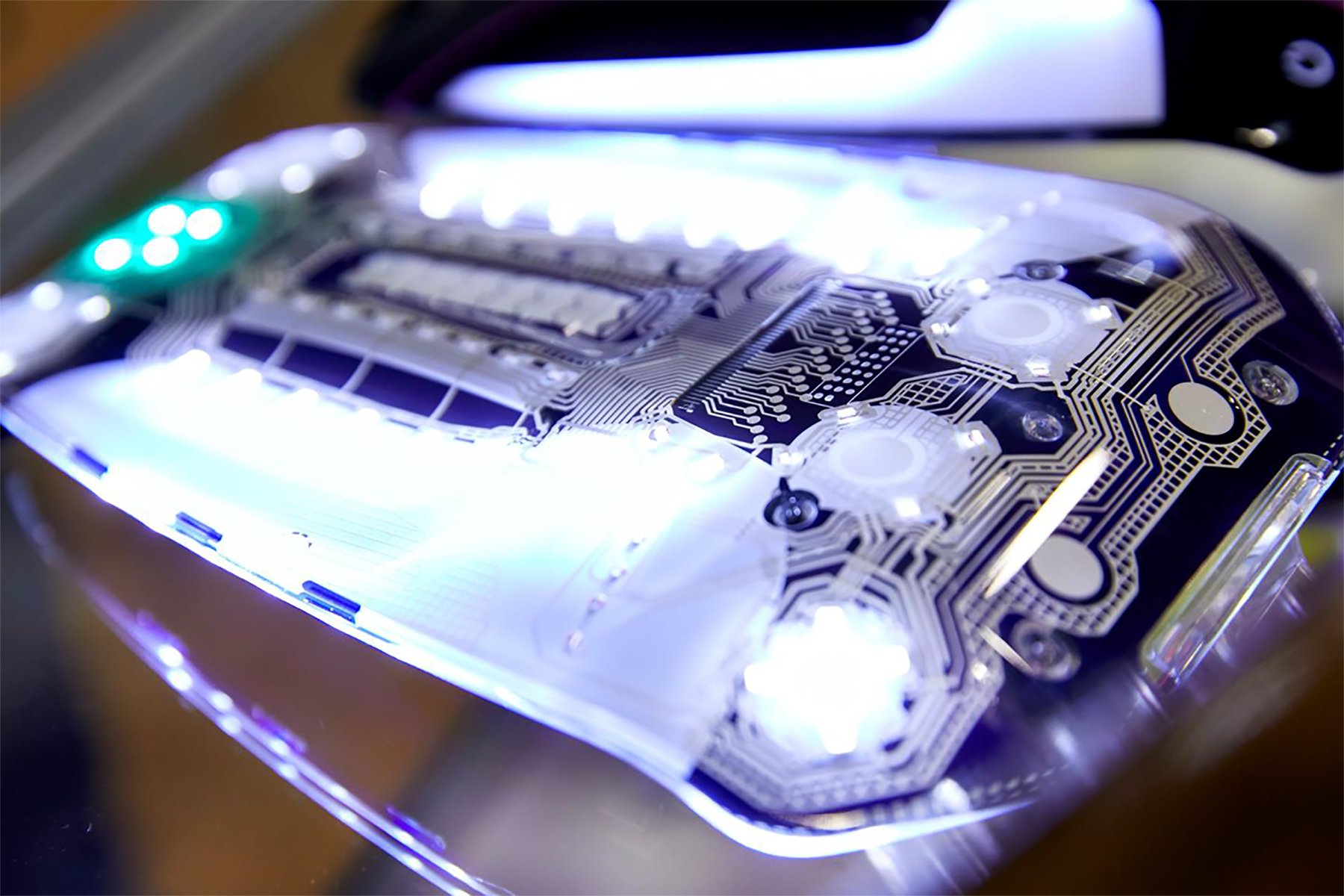

Electrification of the automotive industry

The automotive industry is in the midst of its most significant change in, arguably, the past century. Through a combination of climate change concerns, governmental regulations, and consumer demand, the race is on to produce effective and profitable electrical vehicles. A handful of countries have laid out plans to phase out internal combustion engines over the next two years. Flexible electronics could be an untapped resource in the development of batteries for electric-powered vehicles.

Increased automation and IoT connectivity

It seems like nearly every device is a “smart” device these days – and that’s a trend that’s not going away any time soon. Thanks to flexible electronics and printed sensors, more applications will become automated and connected to the Internet of Things (IoT). From a public perspective, this technology can be used to improve the safety, efficiency, and convenience of utilities and services. Industries can implement RFID and other technologies for asset tracking, fraud protection, enhanced logistics, and making data-informed decisions. Finally, our personal lives and homes will continue to get smarter through smaller, more powerful devices.

Most intriguing uses of printed electronics

With the infinite possibilities of printed electronics, it’s fun to play the “what if” game. The next great innovation may be something we can’t even conceptualize today. You can also find some jaw-dropping renderings and prototypes of devices capitalizing on flexible electronics. However, we’re just as excited about the cutting-edge applications that are already in use today or are realistically on the horizon. Here are just a few examples.

- Printed and flexible sensors – Giving small devices the ability to sense everything from capacitive touch to temperature to biometrics to environmental factors (gas, humidity, etc.).

- Next-generation vehicles – As mentioned earlier, flexible electronics are crucial to the electrification of vehicles, especially when it comes to battery conditioning monitoring. Additionally, printed electronics can be used in advanced driver-assistance systems and creating sleek, high-tech interior customer experiences.

- Wearables and skin patches – Newer devices will be small and flexible enough to stick on the patients’ skin, which will greatly improve remote and continuous patient monitoring, medication adherence, and more.

- Smart clothing – Adding electronics to textiles will allow for discreet biometric monitoring.

- Electrochemical testing strips – In vitro diagnostics will become easier and more accessible for point-of-care use. For individuals with diabetes, this means a less cumbersome and painful way to monitor glucose levels.

- In-mold electronics – For compact, lightweight, and durable devices as well as 3D electronics.

- Smart packaging – Featuring wireless RFID tags, illumination, chemical and temperature printed indicators, electronics articles surveillance (EAS), and more.

Manufacturing partner for flexible electronics

At Tapecon, we have over 25 years of experience producing high-quality flexible and hybrid electronics. We also have close relationships with the leading materials supplier to bring our customers the latest and most advanced solutions. From design consulting to testing to functional printing to custom converting, our team is here to help you shape the future with your innovative devices and components.

Let’s make something great

With over 100 years of manufacturing experience, Tapecon works with product teams to solve challenges, create products, and enhance lives. Learn more about our flexible printed electronics capabilities.