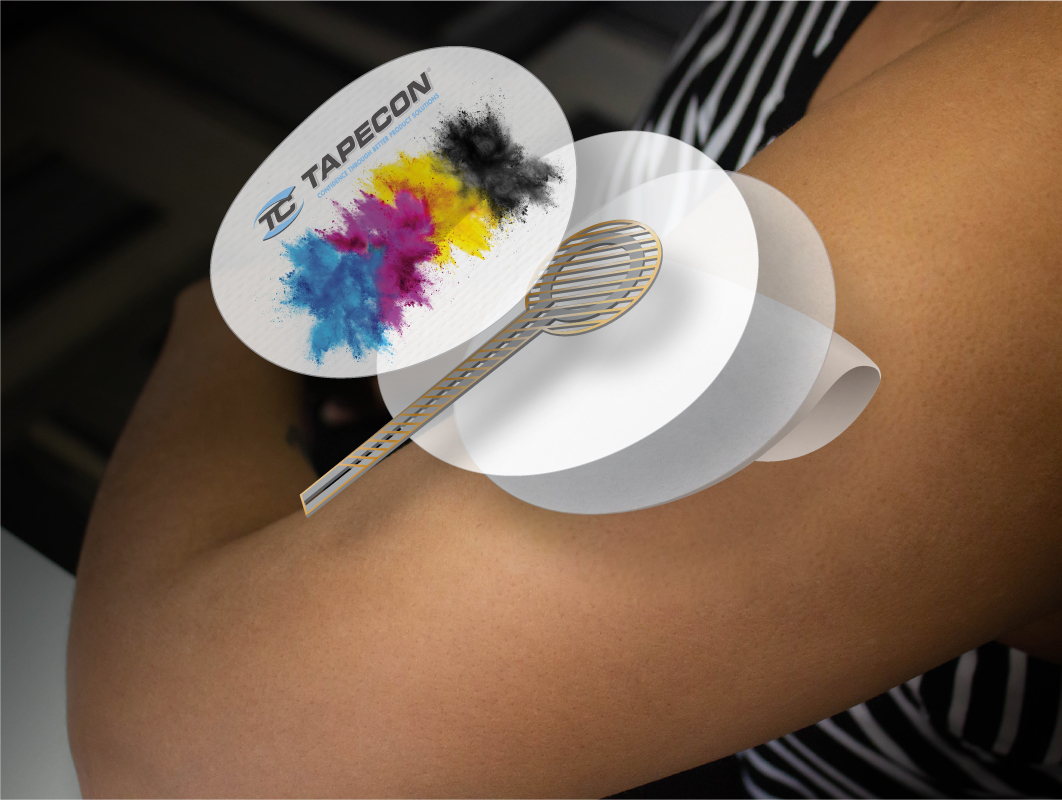

Tapecon at FLEX@SEMICON West 2023

Thank you for visiting us at FLEX@SEMICON West 2023. At Tapecon, we partner with leaders within the Life Sciences industry and their product teams to deliver new and better solutions. Our US based, ISO-13485 advanced manufacturing facility and FDA certified medical grade materials converting, enables solutions from prototyping through full-scale roll-to-roll FHE (flexible hybrid electronics) assembly.

Improve Health and Wellness

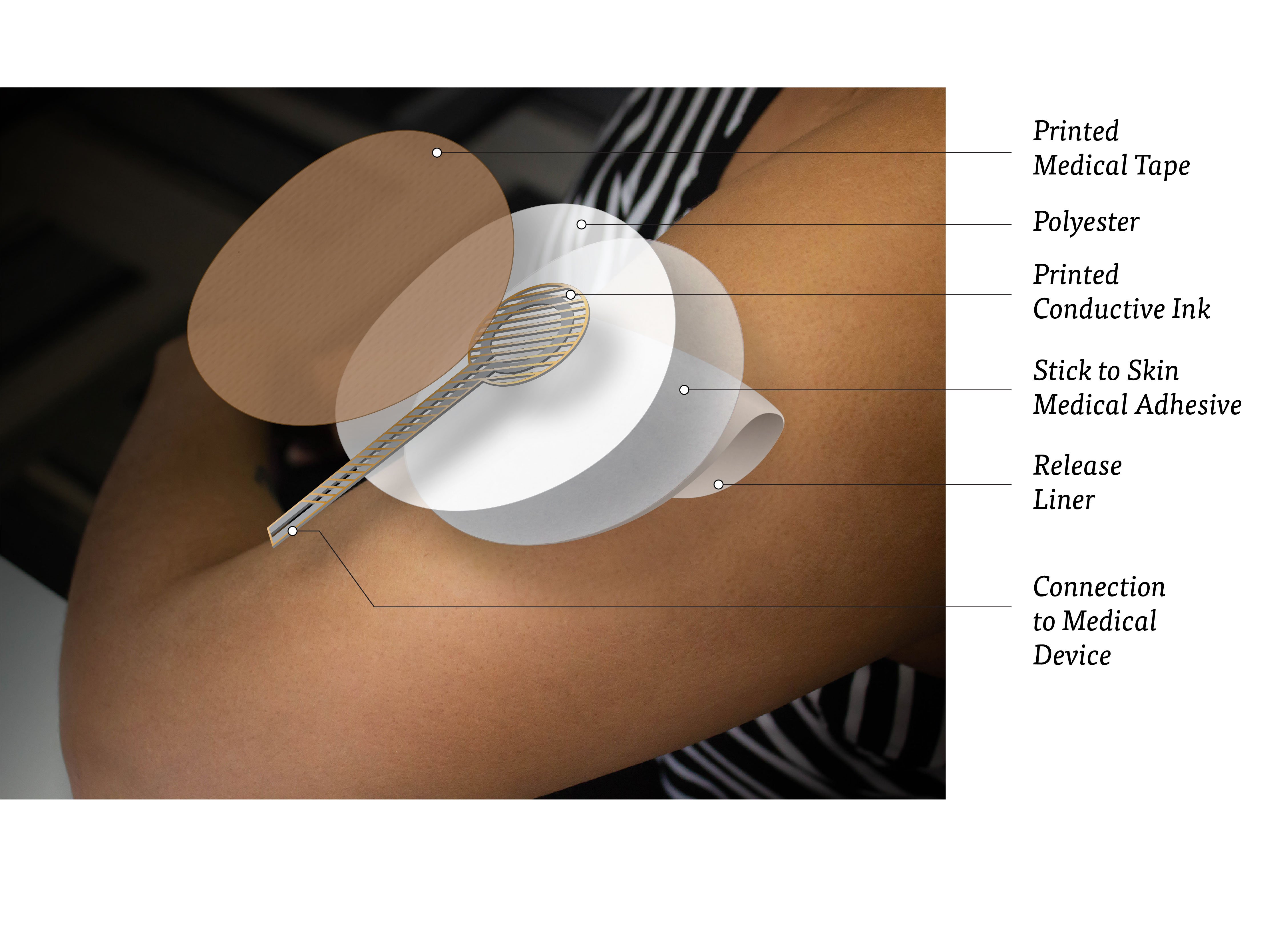

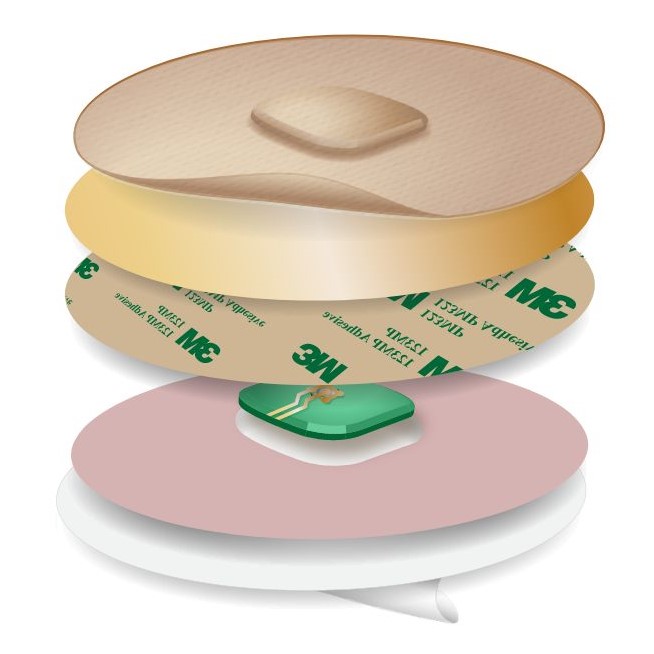

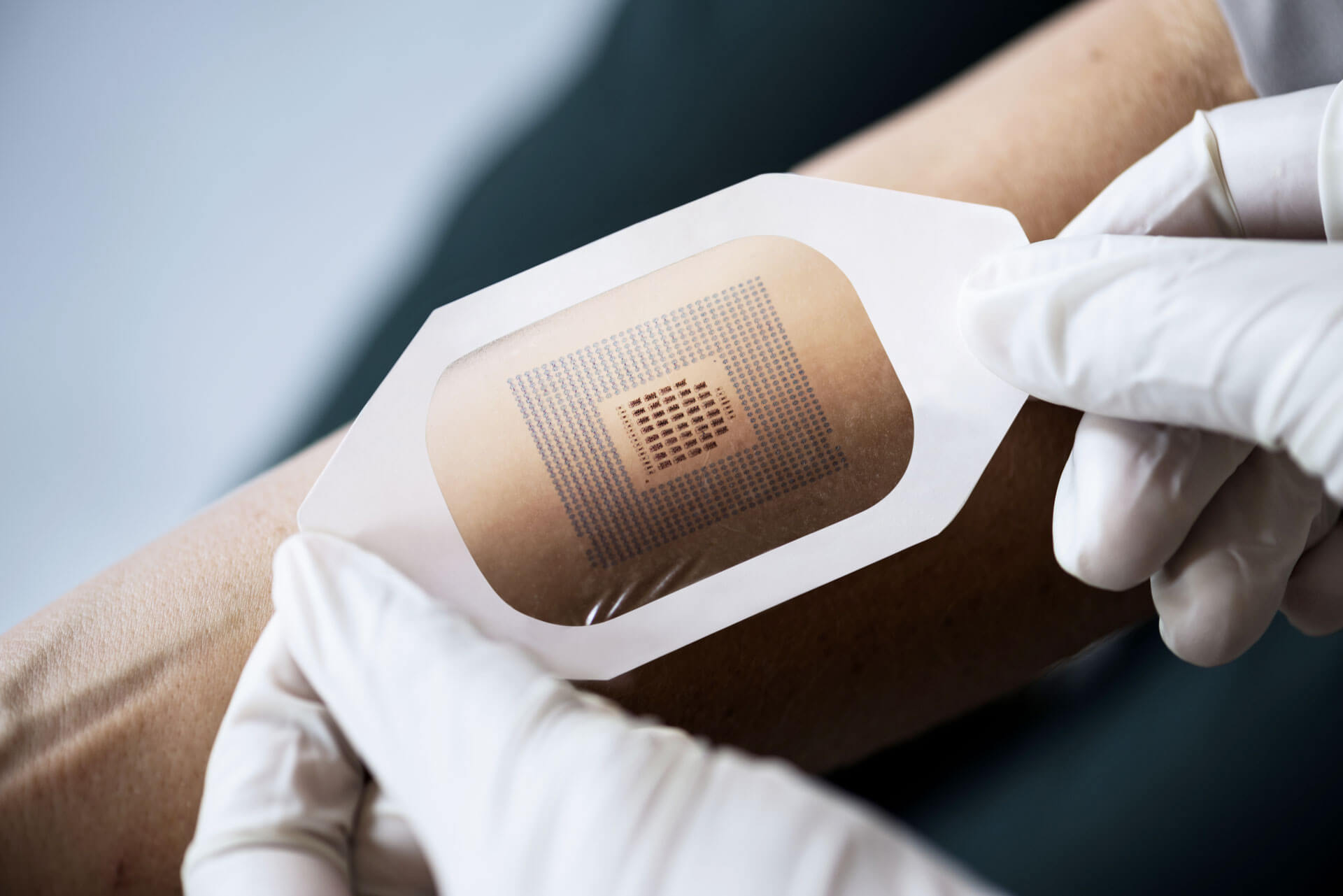

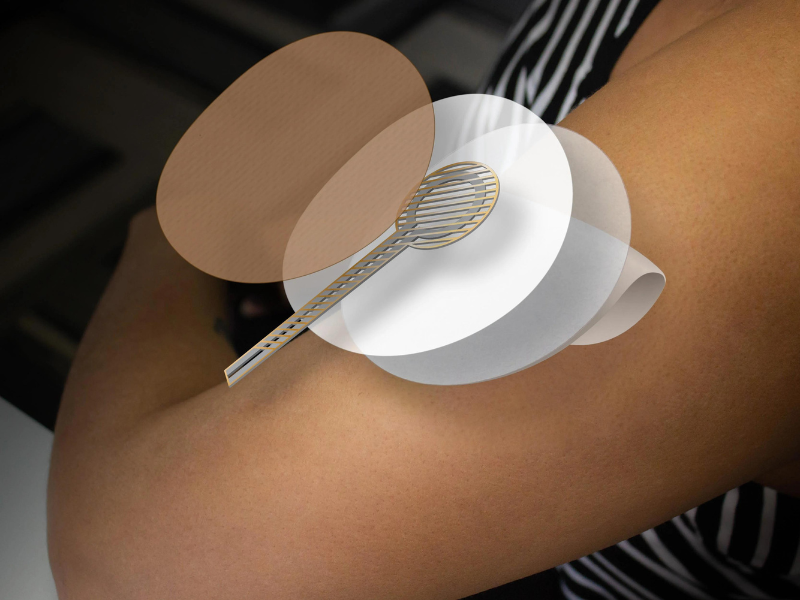

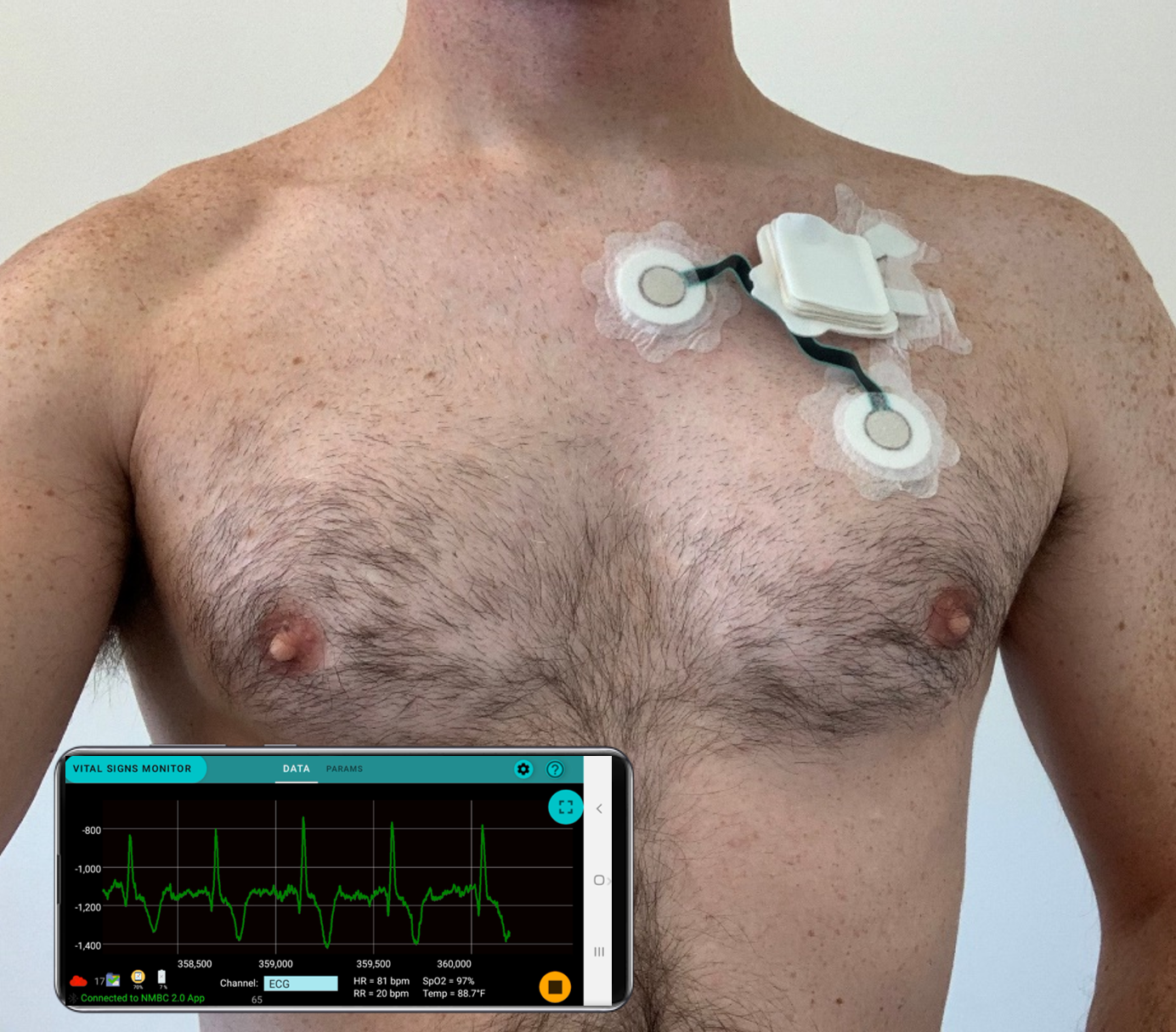

Stick-to-skin wearables hold tremendous potential for enhancing health and wellness. These innovative devices comfortably adhere to the skin and can capture information not only from our bodies vital signs, such as heart rate, blood pressure, respiration rate and temperature, but also from sleep patterns, perspiration, tears, gait and more. Equipped with sensors and advanced technology, they can monitor and provide feedback with different degrees of sophistication. Chemical and electronic indicators can alert wearers once a threshold for a given excursion point has been reached (i.e. Body temperature has exceeded 100℉), Data loggers can record attributes over a prolonged period to provide a broader understanding of past occurrences (i.e. physical activity recorder) The convenience, accuracy, and versatility of electronic stick-to-skin wearables make them a promising tool for promoting healthier lifestyles and fostering a greater sense of well-being.

Remotely Identify Issues

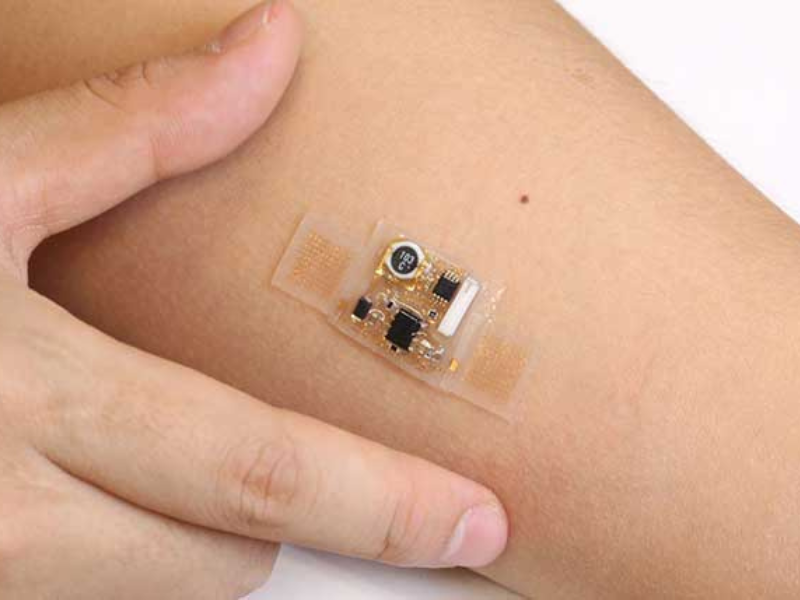

Real-time cloud connected sensors can provide timely insights into one’s immediate health status enabling users to make informed decisions about their well-being or enabling their physicians, care-givers and loved one’s to help them when they can’t be there as often as they’d like. Flexible Hybrid Electronics is transforming at home health by enabling the creation of comfortable, conformal wearables that are noninvasive and affordable. With the ability to wirelessly sync wearables with smartphones via WIFI, NFC, BLE, or WIFI technologies individuals can easily access and analyze their health data, empowering them to take proactive steps towards improving their overall wellness. The convenience, accuracy, and versatility of electronic stick-to-skin wearables make them a promising tool for promoting healthier lifestyles and fostering a greater sense of well-being.

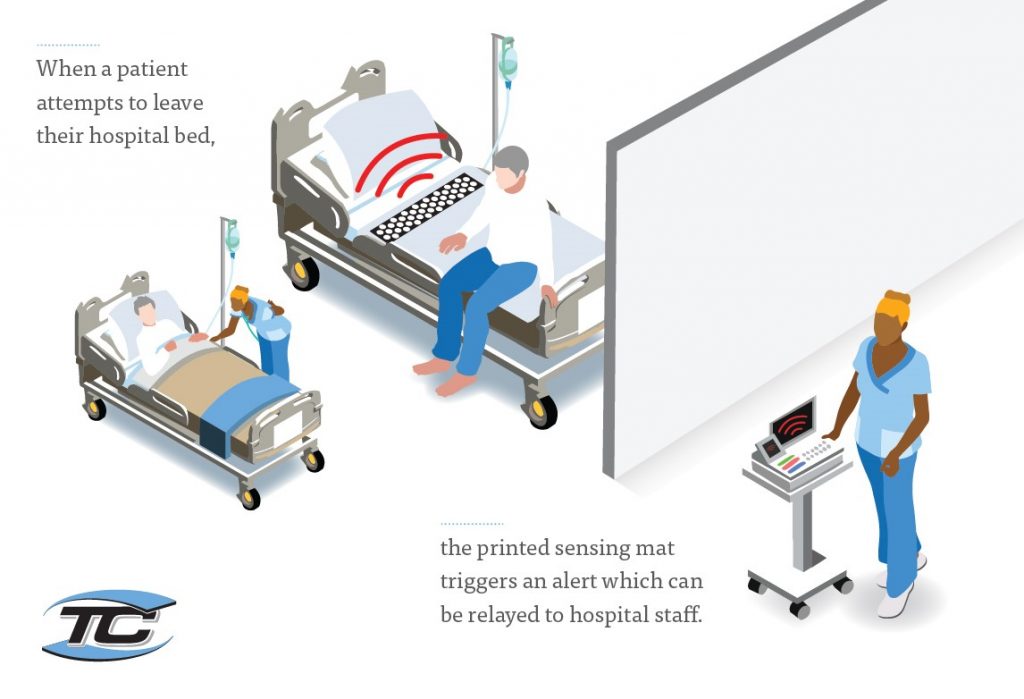

Prevent Negative Outcomes

Electronic skin patches, also called stick-to-skin wearables offers a wide range of benefits in preventing negative outcomes and promoting overall well-being. By continuously monitoring vital signs and health parameters, this advanced wearable can detect early warning signs of potential health issues, allowing for timely intervention and preventive measures. Whether it's monitoring the potential onset of infection, blood glucose levels for individuals with diabetes, tracking heart rate irregularities, or hydration levels, the electronic skin patch provides valuable insights that can help prevent serious complications. Additionally, these patches can be programmed to deliver personalized feedback and reminders, promoting healthy habits such as medication adherence, and to increase physical activity. The convenience and non-intrusiveness of the patch make it an ideal tool for long-term monitoring, especially for those with chronic conditions. By empowering individuals to take proactive control of their health, the electronic skin patch has the potential to significantly reduce negative outcomes and improve overall health outcomes.

Tapecon Applications & Capabilities

Technology & Design Support Stories

Tapecon has helped customers and university partners with design support and production services to help accelerate technology and products.

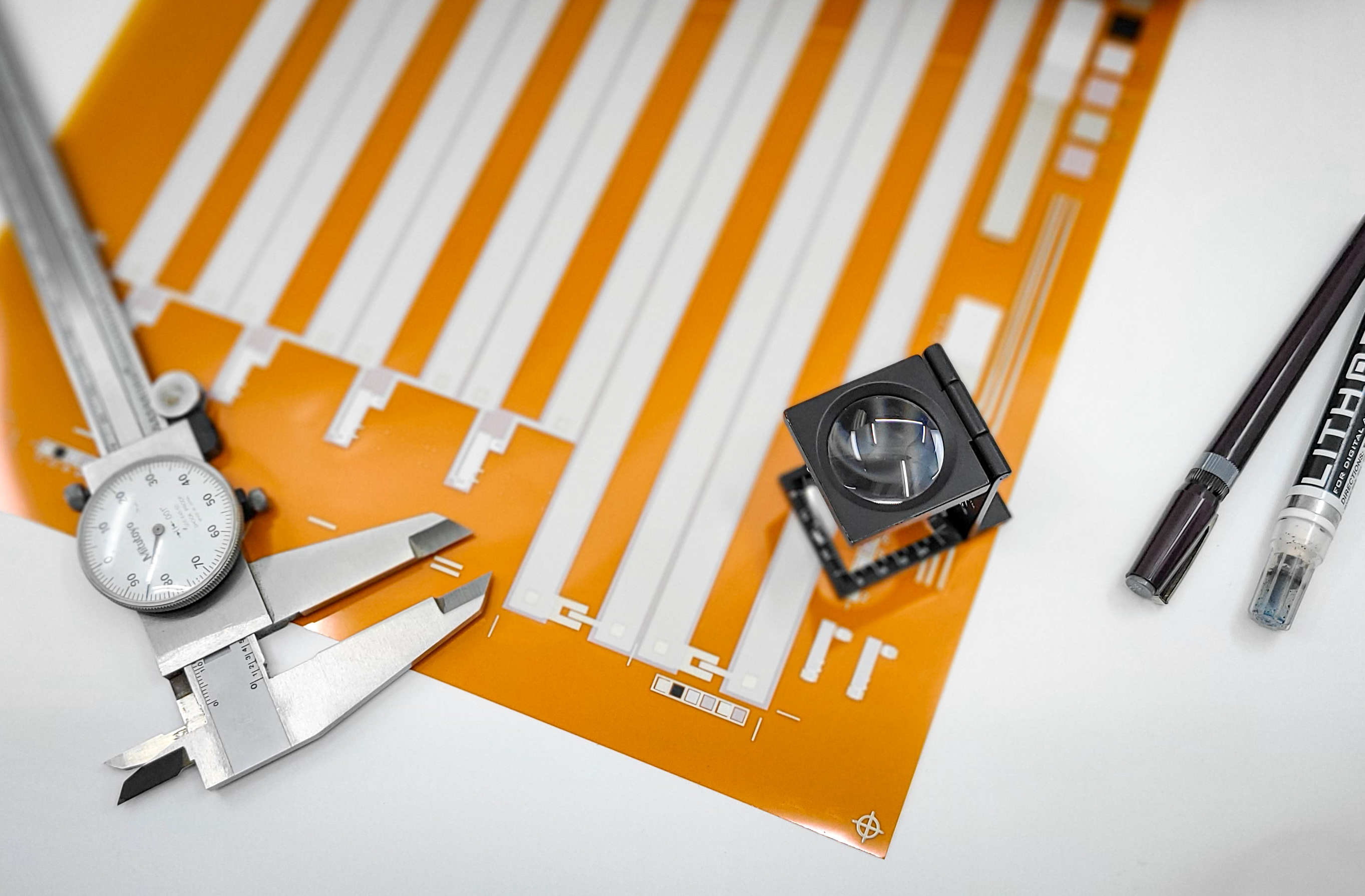

Torque Sensor

Tapecon worked with GE Global Research to design a printed, flexible option to replace a rigid torque sensor. Using our expertise in printed electronics processes and materials, Tapecon was able to manufacture a more accurate & lighter weight sensor that was a lower cost compared to etched copper options.

Wearable Temperature Sensor

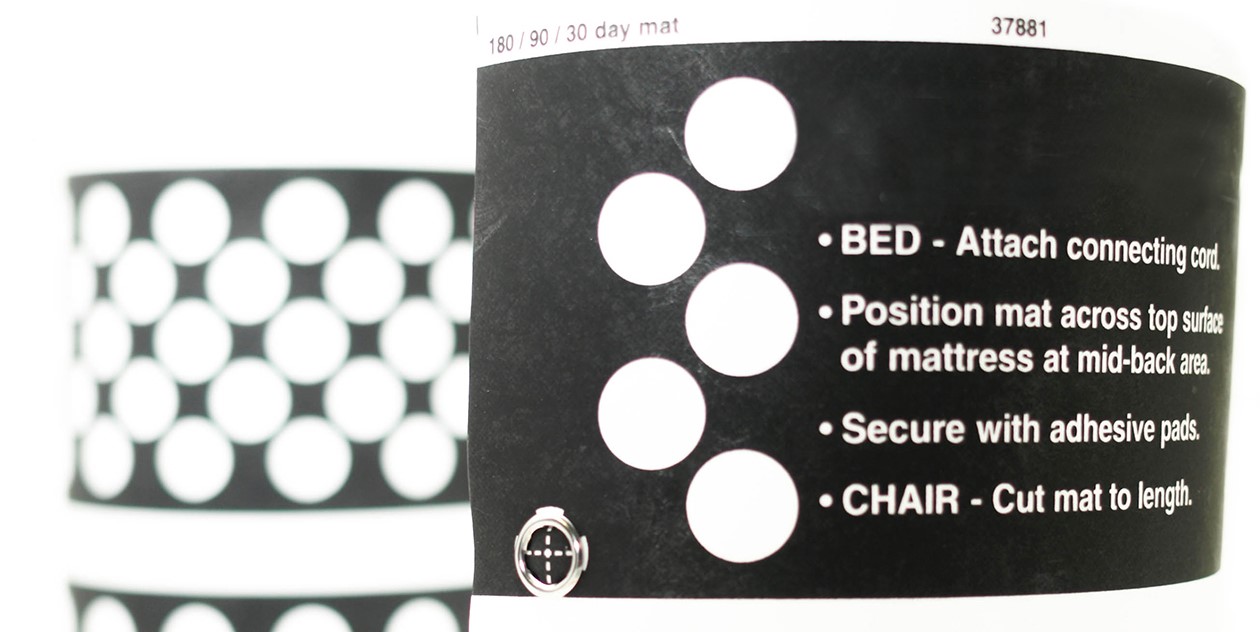

Tapecon partnered with Binghamton University to prove FHE capability, viability and manufacturability of a wearable temperature sensor. The project involved updated design for manufacturing, printing conductive inks, placing components and adding a wearable stick to skin substrate with top graphics.

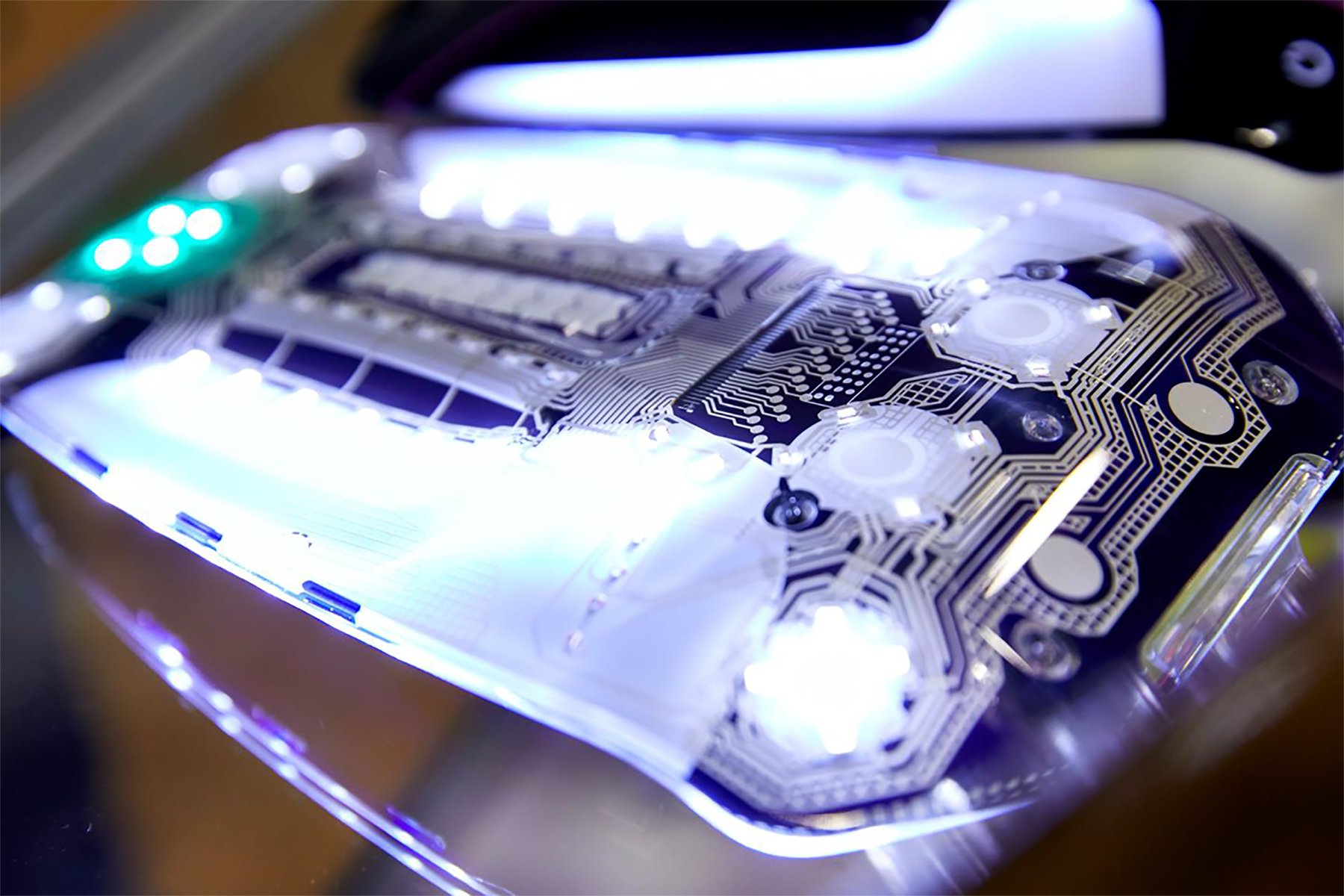

Wearable Monitor Circuits

Tapecon worked with GE Global Research to help build and complete circuits for a wearable monitor. Tapecon's engineering team became an extension of the GE Research project team and was able to work through design iterations to provide optimal prototypes. Ultimately, Tapecon was able to help meet quick deadlines for prototypes and create designs that were ready for scalable manufacturing. Including a manufacturing partner in the early stages allow the process to move more efficiently.

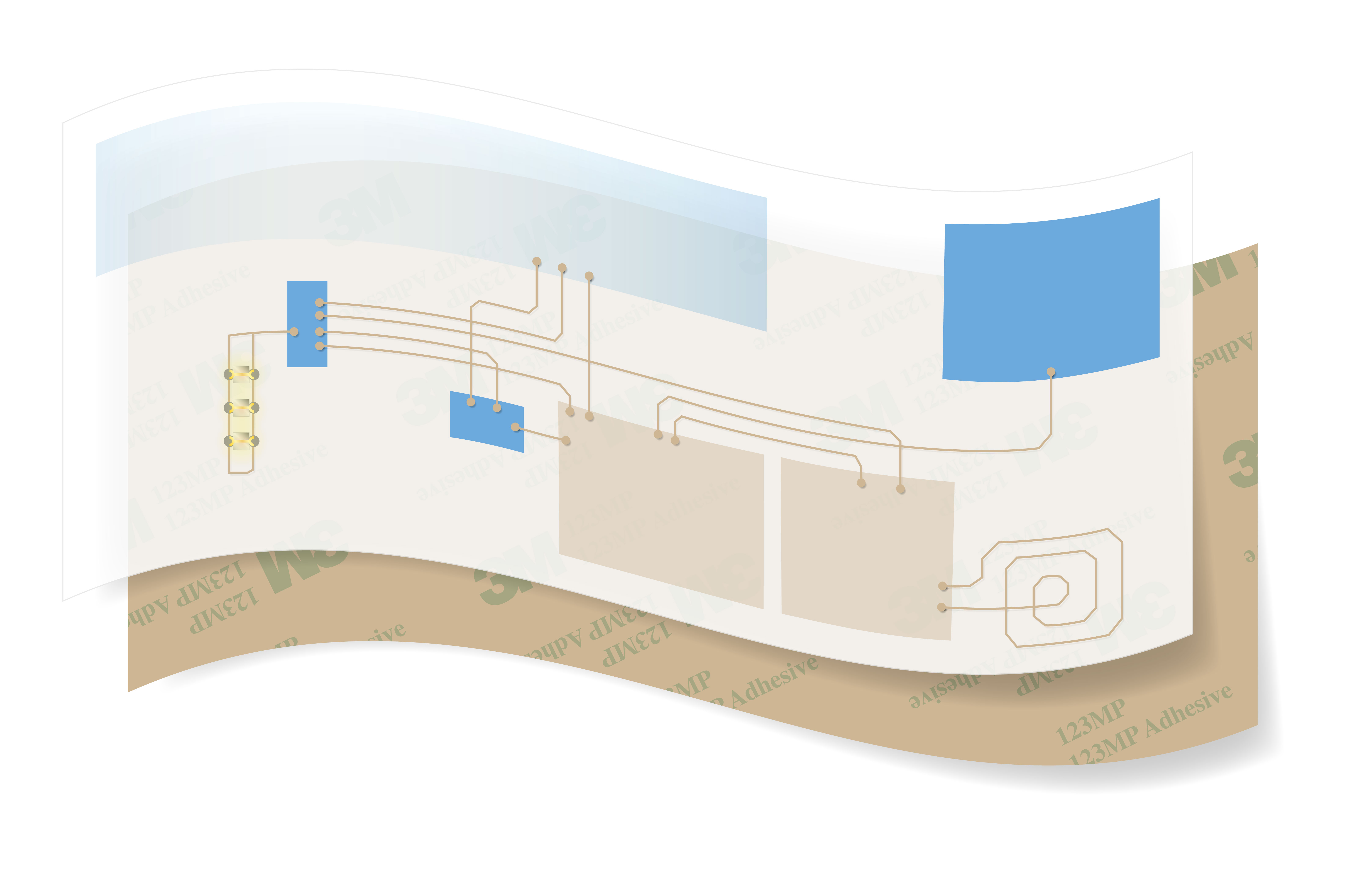

Human Vital Sign Monitoring Device

The collaborative partnership between GE Research, Binghamton University and Tapecon with the support of NextFlex, SEMI Fextech, NBMC, and NYS ESD has resulted in a highly advanced device that has the potential to revolutionize healthcare by enabling accurate and real-time monitoring of vital signs in a wide range of settings. Tapecon aids in the manufacturing and in designing for manufacturing to apidly advance protoypes.

meet the team

Steve Davis

President

Steve Davis is the President at Tapecon, Inc., a 5 generation, family-owned manufacturer based in Buffalo, New York. Tapecon partners with product teams to develop, scale, and deliver better products through responsive and reliable printing, converting, and advanced manufacturing. Tapecon provides expertise in specialized printing and converting, printed flexible electronics, and manufacturing of disposable devices for medical and industrial markets. Steve's efforts have created a progressive culture of innovation at Tapecon over his fifteen years with the company.

Rafael Tudela

Technical Program Lead - Flexible & Printed Electronics

Rafael has a background in Electrical and Electronics Engineering with responsibilities for the design and development of flexible hybrid electronic devices that fulfill client requirements for high-throughput manufacturing operations at Tapecon. Rafael is a Project Leader who works with clients and Tapecon’s production managers to transform client concepts into robust manufacturing operations. Rafael has significant experience designing flexible circuits using additively printing operations for medical devices.

Brad Hull

Printed Electronics Solutions - Business Unit Director

Brad Hull leads the printed and flexible hybrid electronics business unit for Tapecon, a 100yr old Buffalo, NY based custom converting company. Brad’s 35 years of business strategy, commercialization and revenue growth expertise has been focused within functional printing and converting technologies including: AIDC, RFID, Sensors and IoT, Printed Electronics, FHE, Wearables, Intelligent Packaging, Labels and Custom Converting. Brad has a passion for disruptive technology and creating win-win business relationships.

Related Resources

About Tapecon

For over 100 years, Tapecon has partnered with product teams to develop, scale, and deliver better products through responsive and reliable printing, converting, and advanced manufacturing.

Tapecon provides expertise in specialized printing and converting, printed flexible electronics, and contract manufacturing of disposable devices for medical and industrial markets. Established in 1919, Tapecon is a 5-generation, family-owned business based in Buffalo, New York.

Quality & Compliance

Tapecon ensures that we meet your demanding product specifications through our quality management system and a wide assortment of tools and equipment.

LET'S CONNECT

Use this form to inquire about a project or submit a question. Upon submission, someone from our team will follow-up with you as soon as possible, but always within 1 business day.