Innovating the Future of Technology in Healthcare and Wearables

Embark on a collaborative journey with Tapecon and UB, exploring the future of Stick-to-Skin wearable technology.

This showcase bridges academia and industry, offering a platform for innovative ideas to transition from concepts to market-ready solutions.

Projects aligning with Tapecon's manufacturing capabilities stand to receive considerable support through financial investment from Tapecon up to $50,000, in-kind development, prototyping, and commercialization assistance. Selected projects may engage in joint collaboration with Tapecon to also pursue grant funding from various associations and governmental entities.

Seize the opportunity to merge creativity with manufacturing prowess for groundbreaking advancements in wearable tech.

February 27th, 2024 @ 2:00 PM – 5:00 PM

University at Buffalo Campus, Davis Hall, Room 230A

Event Highlights

- Exclusive Showcase: Explore innovative new wearable applications and research projects developed across UB’s distinguished faculty and Tapecon’s industry experts.

- Networking Powerhouse: Engage in meaningful discussions with fellow researchers, industry leaders, and potential mentors, unlocking doors to future product development, prototyping, scaled manufacturing and commercialization collaborations.

Who Can Attend?

- UB Faculty Members: This event is primarily for faculty members spearheading research initiatives.

- Their Graduate Students: Faculty members are encouraged to bring along 1-2 graduate students who are integral to their research projects, offering them a platform to shine and learn.

Our Shared Vision

- UB and Tapecon's collaboration is more than just a meeting of minds; it's a commitment to building a symbiotic relationship that benefits both academia and industry.

We aim to create a space where innovative ideas are not just shared but are nurtured to flourish into real-world applications. - Catalyst for Opportunities: Explore how this partnership can lead to exciting prospects like joint research funding, Go-To-Market (GTM) opportunities, internships, materials and scaled converting support, and more.

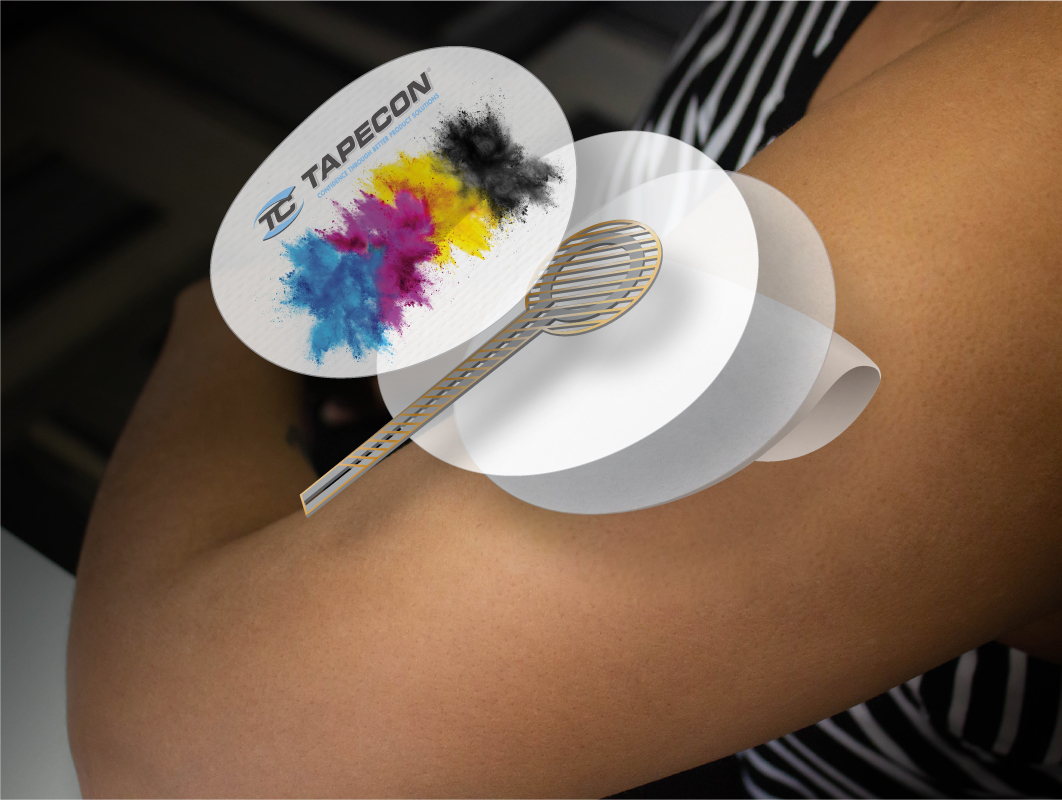

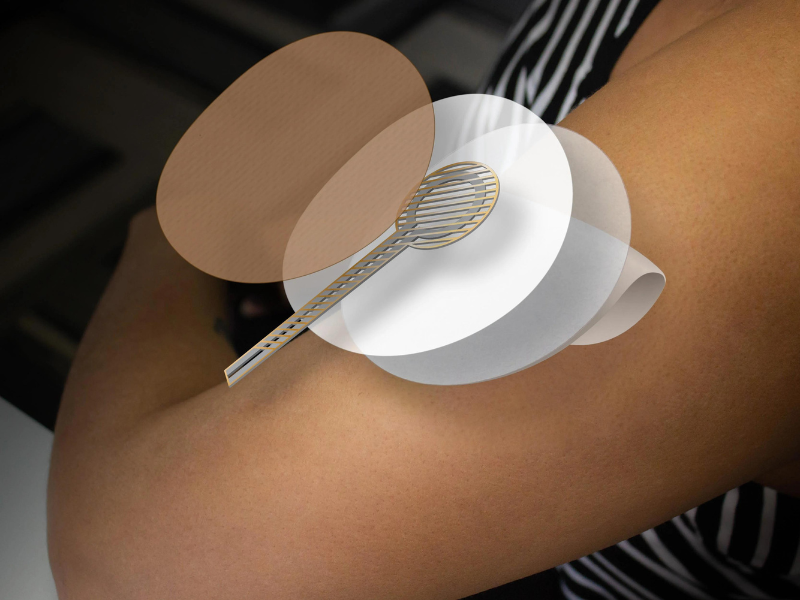

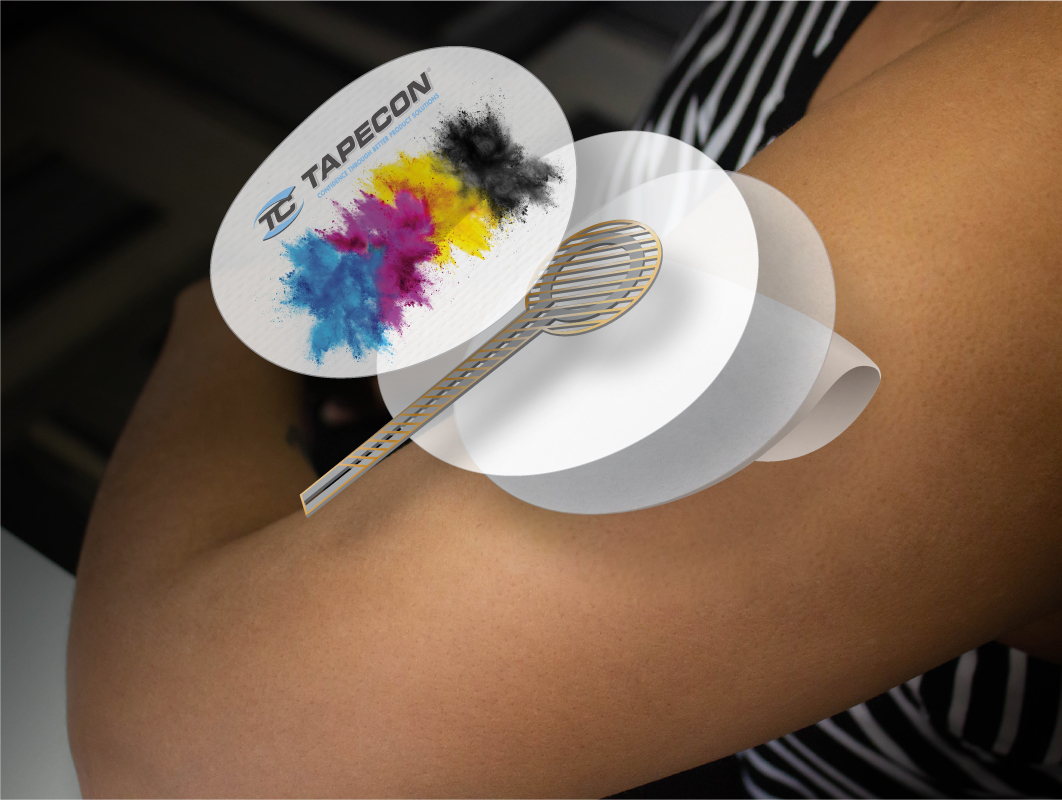

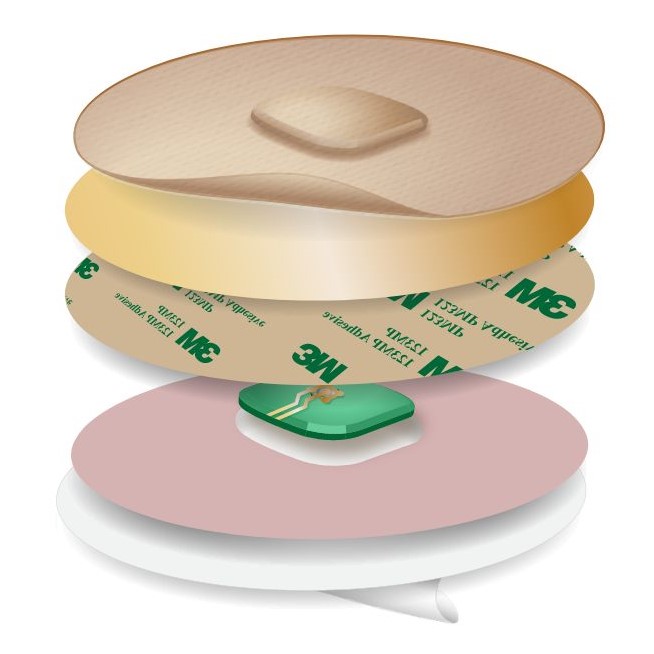

On-Body Wearable Patch Biosensors

Coated Micro-Needle Technologies in Skin Wearable Patch Form

Novel Vital Sign Detection Techniques

Microfluidics

Organic Compound Detection

Biometric Sensing Technologies

Fluid Velocimetry

Technology & Design Support Stories

Tapecon has helped customers and university partners with design support and production services to help accelerate technology and products.

Wearable Temperature Sensor

Tapecon partnered with Binghamton University to prove FHE capability, viability and manufacturability of a wearable temperature sensor. The project involved updated design for manufacturing, printing conductive inks, placing components and adding a wearable stick to skin substrate with top graphics.

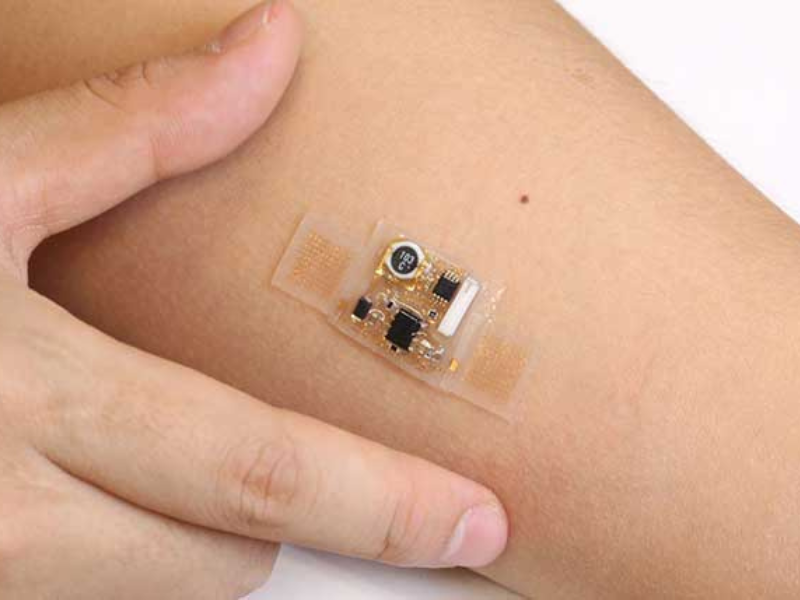

Wearable Monitor Circuits

Tapecon worked with GE Global Research to help build and complete circuits for a wearable monitor. Tapecon's engineering team became an extension of the GE Research project team and was able to work through design iterations to provide optimal prototypes. Ultimately, Tapecon was able to help meet quick deadlines for prototypes and create designs that were ready for scalable manufacturing. Including a manufacturing partner in the early stages allow the process to move more efficiently.

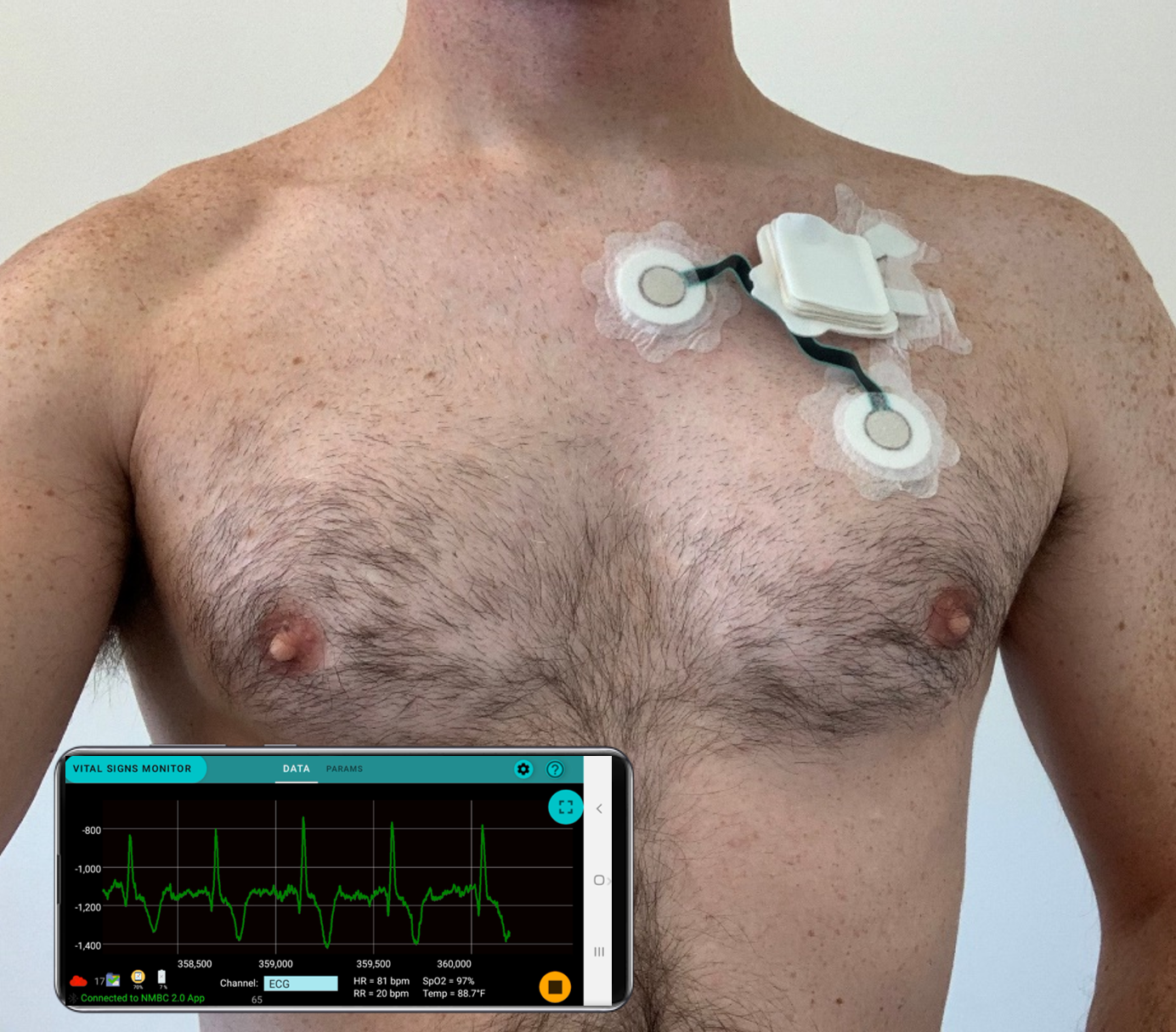

Human Vital Sign Monitoring Device

The collaborative partnership between GE Research, Binghamton University and Tapecon with the support of NextFlex, SEMI Fextech, NBMC, and NYS ESD has resulted in a highly advanced device that has the potential to revolutionize healthcare by enabling accurate and real-time monitoring of vital signs in a wide range of settings. Tapecon aids in the manufacturing and in designing for manufacturing to apidly advance protoypes.

Related Resources

MEET THE TEAM

Steve Davis

President

Steve Davis is the President at Tapecon, Inc., a 5 generation, family-owned manufacturer based in Buffalo, New York. Tapecon partners with product teams to develop, scale, and deliver better products through responsive and reliable printing, converting, and advanced manufacturing. Tapecon provides expertise in specialized printing and converting, printed flexible electronics, and manufacturing of disposable devices for medical and industrial markets. Steve's efforts have created a progressive culture of innovation at Tapecon over his fifteen years with the company.

Rafael Tudela

Technical Program Lead - Flexible & Printed Electronics

Rafael has a background in Electrical and Electronics Engineering with responsibilities for the design and development of flexible hybrid electronic devices that fulfill client requirements for high-throughput manufacturing operations at Tapecon. Rafael is a Project Leader who works with clients and Tapecon’s production managers to transform client concepts into robust manufacturing operations. Rafael has significant experience designing flexible circuits using additively printing operations for medical devices.

Brad Hull

Printed Electronics Solutions - Business Unit Director

Brad Hull leads the printed and flexible hybrid electronics business unit for Tapecon, a 100yr old Buffalo, NY based custom converting company. Brad’s 35 years of business strategy, commercialization and revenue growth expertise has been focused within functional printing and converting technologies including: AIDC, RFID, Sensors and IoT, Printed Electronics, FHE, Wearables, Intelligent Packaging, Labels and Custom Converting. Brad has a passion for disruptive technology and creating win-win business relationships.

Not a Research Presenter?

If you are interested in attending just to observe and NOT present, please register here:

Registration is open until February 14th, 12 AM, EST

Observer Registration

Research Presenter Registration

About Tapecon

For over 100 years, Tapecon has partnered with product teams to develop, scale, and deliver better products through responsive and reliable printing, converting, and advanced manufacturing.

Tapecon provides expertise in specialized printing and converting, printed flexible electronics, and contract manufacturing of disposable devices for medical and industrial markets. Established in 1919, Tapecon is a 5-generation, family-owned business based in Buffalo, New York.

.jpg)