By now, most companies understand the importance of a sustainability plan – the challenge is knowing where to start. Labels and packaging are often a reasonable entry point into sustainable manufacturing since they contribute to a high level of waste. Plus, modifying these items rarely directly impacts the quality or performance of the primary product, resulting in lower risk.

Here are three relatively simple ways to improve the recyclability of your labels and packaging through more sustainable materials selection and printing techniques.

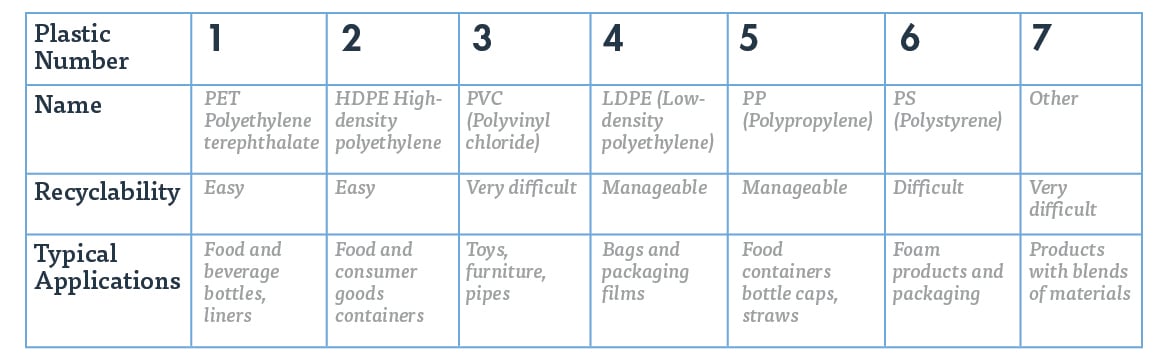

1. Evaluate plastics for recyclability.

By the latest estimates, the world produces over 418 million tons of plastic per year. Packaging represents the largest producer with 42% of primary plastic. While recycling has increased over the past few decades, only about 20% of plastic waste was recycled (source: OurWorldinData.org). For the majority of plastic that is discarded, it can take between 20 to 500 years for the material to decompose.

To improve the sustainability of products and packaging, manufacturers should be aware of recyclability for each type of plastic. In general, multi-polymers make recycling more difficult. When possible, the use of PET, HDPE, or compostable plastics is the more sustainable option.

2. Prioritize deinking for paper products.

As paper recycling becomes increasingly important, manufacturers and printers must be aware of deinkability and take the necessary steps to improve their paper products’ recyclability. Deinking is the process of separating and removing ink from printed graphics on paper products. The goal is to remove as much ink as possible in order to recycle the paper at a similar quality level as the original product. If a high level of deinking is not possible, then the paper may be recycled for lower-grade paper products.

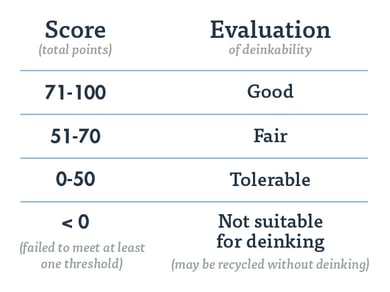

A common way of determining the recyclability of paper products is by calculating the Deinkability Score. Created by the European Paper Recycling Council, the Deinkability Score is based on five parameters – luminosity, color, cleanliness, ink elimination, and filtrate darkening. The Deinkability Score is the summation of individual category scores; however, the product must meet a minimum threshold in each category to be suitable for deinking.

Deinkability Score Results

3. Switch to dry toner for industrial printing.

Replacing chemical toner with dry toner for your industrial printing process has several environmental benefits:

- Dry toner particles are mechanically altered (size and shape), whereas chemical toner particles are modified in a solution

- Printing with dry toner consumes less energy and water than chemical toner

- Dry toner can produce less waste

- Certain dry toner products have deinkability scores of 90 and above, guaranteeing recyclability of printed products on recyclable materials

- Dry toners for labeling and packaging products are approved and safe for food, toys, and clothing

Take a deeper look at sustainable manufacturing

To learn more about how your company can help make a better, greener future, we invite you to download Tapecon’s Sustainability Guide for manufacturing, printing, and materials selection.

Let’s make something great

With over 100 years of manufacturing experience, Tapecon works with product teams to solve challenges, create products, and enhance lives. Learn more about our sustainability initiatives.